Trusted by the best

For over 75 years

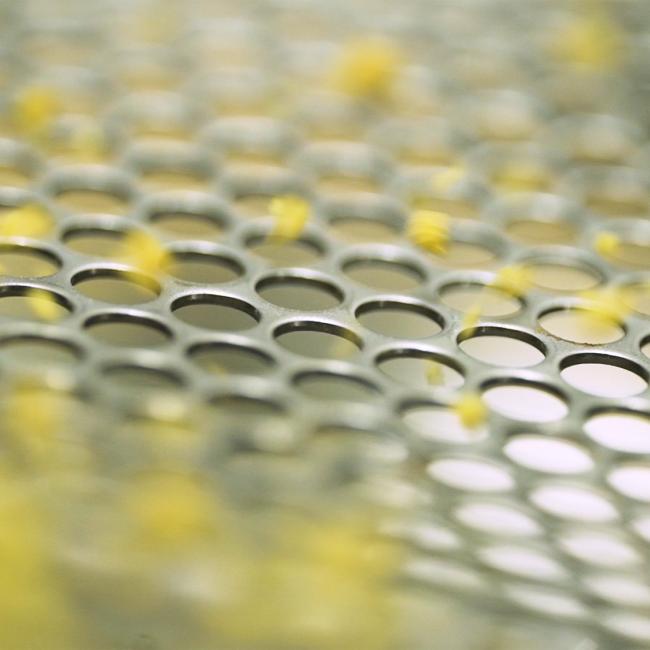

In 75 years, Dinnissen Process Technology has grown to become a market leader and system integrator in the process technology of powders, granules, and granulated products. We are proud that the world's best producers rely on our machines, systems, and process lines.