Customer Story: Perstorp Waspik

Customer Story: Perstorp Waspik

The new mixing line from Perstorp Waspik: from product intake to automation and control

Perstorp operates in 22 countries and is a global leader in chemical innovation. Perstorp's Dutch branch focuses mainly on compound feed additives. In this customer story, Jos Falvay, project manager at Perstorp Waspik, explains how the search for a producer of a completely new mixing line for powders led to a partnership with Dinnissen.

"WHAT CHARMED US MOST ABOUT DINNISSEN WAS THAT THEY RESPONDED PERFECTLY TO OUR QUESTIONS EACH TIME: THEY JUMPED RIGHT IN AND QUICKLY CAME UP WITH A TAILOR-MADE SOLUTION TO EACH PROBLEM."

Perstorp on the collaboration

"The collaboration with Dinnissen came about relatively recently. We were looking for a completely new line for mixing powders. It was important to us to have just one company develop the entire process, from product intake to control and automation.

The name Dinnissen was already familiar to us; from my past in the compound feed industry, I had heard many good stories. When choosing a partner for this project, Dinnissen also came out strongly. First of all, during a visit I was very impressed by the modern production facilities, the work they do, the materials they work with: everything looked very professional and well cared for. It became clear to me that Dinnissen pays a lot of attention to hygiene; this is very important in our sector.

The experts at Dinnissen made sure they always had an answer to our questions. It soon became clear that they were not just a company that implements their machines. Together with us, they took on the challenge of taking the whole thing to the next level. By thinking along with us, they helped to develop the mixing line. Of course, price is important, but Dinnissen's expertise and flexibility as a partner were essential factors for us."

Our Big-Bag stations on site at Perstorp Waspik.

Always critical

"What characterizes Dinnissen is that after the complete mixing line was implemented, their inspectors critically checked everything again on site to make sure everything was correct and the installation of the production line was to our satisfaction.

One of these checks revealed that the screws of the new silos had a pitch that was too small, which caused our product to recede down. When this error was discovered, Dinnissen immediately took full responsibility. They gave their all to solve this problem. It is impossible to prevent all errors, but to us, the most important thing is that we can count on responsibility being taken and everything being solved in the right way. Dinnissen handled this well.”

"We are confident that the machines will last a long time, it's just very solid stuff."

sparring partner

"Throughout this process, we experienced working with Dinnissen as a partner as very pleasant. The Dinnissen project manager was always on top of things and made sure the project kept running. Regular meetings were organized to discuss progress. The collaboration was simply excellent: We knew who we could approach and what we could ask them for. Everything was arranged down to the last detail. In addition to being our point of contact, Dinnissen was also a sparring partner; they clearly expressed their opinion and thought along with us about how the project could be optimally designed."

Confidence in the collaboration

"The entire mixing line was recently delivered to us and we are now testing everything. Dinnissen is also closely involved in this, in order to solve any possible problems adequately and quickly.

Dinnissen's machines are of very good quality and as a partner they respond quickly to our requests. We look to the future with confidence and are very satisfied with the collaboration so far."

Jos Falvay - Projectmanager at Perstorp Waspik

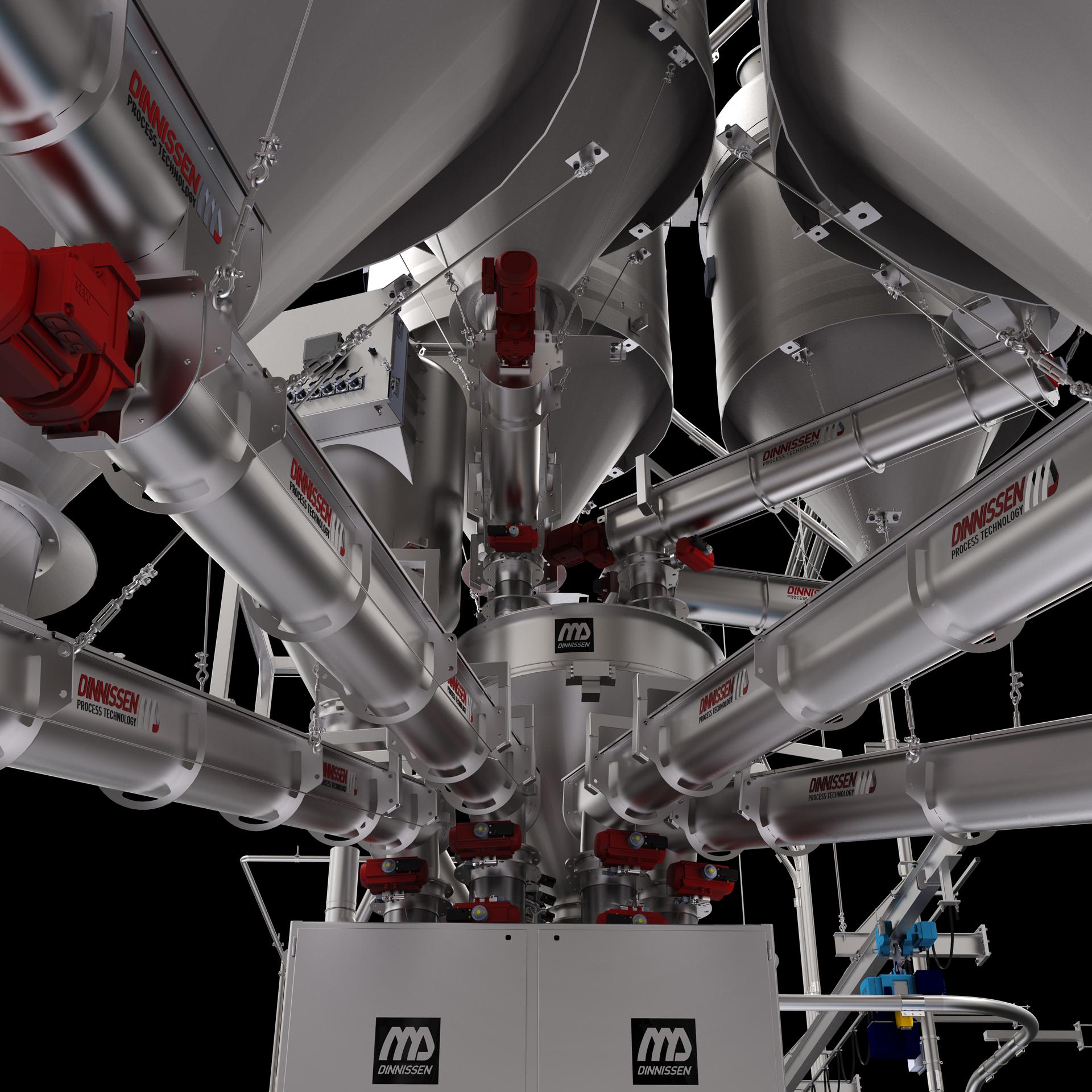

An overview of the installation with a mixer on the 1st floor.