'No-touch' process equipment improves food safety

'No-touch' process equipment improves food safety

With the growing global population and prosperity, the demand for high-quality, safe food is also increasing. Therefore, hygiene guidelines for the industry are becoming increasingly stringent. Process equipment plays a crucial role in this. And machine builders are responding with tailor-made innovations. Contributing to food safety is also the vision underlying the ambition of Dinnissen Process Technology.

Anouk van Veen and Han Joosten, experts at Dinnissen, were interviewed by Solids Magazine. In this news article, we share some highlights from the interview, including how our 'no-touch' process equipment contributes to improved food safety.

EHEDG guidelines

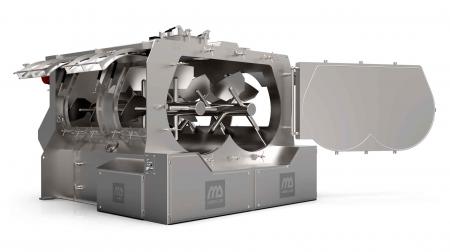

Dinnissen's machines are expertly designed. "Our designs adhere to the guidelines set by the European Hygienic Engineering & Design Group (EHEDG)," says Van Veen. "We minimize the use of welds, bolts, and nuts in our equipment, avoiding dead spaces. Bearings are positioned exclusively on the exterior and are flushed with compressed air to prevent any ingress or egress from the machine. Features of our machines include mixers with retractable shafts and tiltable hoppers. Components are not only easily accessible but also designed for quick and efficient cleaning." Additionally, all machine parts undergo a surface treatment at Viwateq to achieve superior smoothness and enhanced cleanability.

'NO-TOUCH' INSTALLATIon

The next step is to build machines that require minimal cleaning: the 'no-touch' installation. "To manually dry-clean an installation, it needs to be opened, which poses risks to food safety," Van Veen points out. "For instance, foreign objects can enter the installation. Our aim is for our machines to remain closed as long as possible during production. The process is designed to leave a minimum amount of residue in the installation."

COMPRESSED AIR CLEANING

"We encourage our prospective clients to speak with our existing customers," says Van Veen. "This provides invaluable insights. For example, a potential customer recently learned from a current client that our installation, due to its minimal residue production, required cleaning only once a week. This allows for continuous batch processing without disruptions. Our goal is to further extend this duration. We're not only enhancing automation but also introducing novel applications, such as compressed air cleaning systems. These systems internally dry and cleanse a machine after each batch, working in conjunction with beaters and extraction units. Essentially, we're replicating the tasks of an operator, but without the need to open the machine. This is truly groundbreaking. In the near future, cleaning duration will become negligible."

AUTOMATIC SAMPLING

"Our aim is for food companies to produce from 'white to red'," Joosten explains. "Our process installations are often used for multiple recipes. The goal is for producers to consecutively manufacture batches tailored to increasingly stringent standards without needing to halt operations for interim cleaning. Only when reaching products that need to be allergen-free, for instance, is cleaning required. 'Smart design' makes this feasible." Van Veen cites the development by Dinnissen of an automatic sampler as an instance of such smart design. "This means that operators no longer need to manually open a hatch to collect a sample. Such actions can adversely affect food safety."

Food Safety: 5 Tips for Manufacturers

- Stay Updated with Current Food Safety Guidelines: Always adhere to the latest food safety standards that a product needs to meet. These are the criteria that companies are audited against during their certification processes.

- Monitor Ambient Air Around Equipment: Especially if it is used in the production process. Does the surrounding air meet the standards required for producing a high-quality product?

- Prevent Foreign Objects in Equipment: Whether it's an operator's knife, a screwdriver, or a simple cable tie, these items should never be inside your equipment. Ensure that metal detectors and sieves are frequently checked for proper functionality.

- Implement Sieves Early in the Production Process: Don't just place sieves at the end of the process during packaging. Product quality starts with the intake of raw materials at the beginning. Prevent contaminants from entering the process. Product checks and sample analyses are the manufacturer's responsibility, as they have complete knowledge about the product.

- Invest in Proper Training for Staff: No matter how safely a machine is designed and constructed, a significant responsibility rests with the operators using them.

Would you like to learn more about how we ensure food safety with our solutions? Please feel free to contact one of our specialists.

Do you have a question about your process?

- Over 75 years of experience in your industry as a system integrator

- Everything under one roof: engineering, production, testing, installation, control, and service

- Always a tailor-made solution for your entire process.