Year in Review 2023

Year in Review 2023

In 2023, Dinnissen celebrated a special milestone: its 75th anniversary. Since 1948, Dinnissen has been 'trusted by the best', and we're celebrating this with a collection of all the customer stories from this remarkable year. In these ten articles, we highlight the various projects and collaborations that have contributed to the success of Dinnissen and its clients worldwide. These stories demonstrate Dinnissen's commitment to innovation, customized solutions, and the pursuit of achieving the best possible outcomes for our customers.

How Solan improved production capacity by 400% with their new Pegasus mixing line

In 2021, Solan Kraftfutterwerk, an Austrian animal feed production company, entered into a collaboration with Dinnissen to establish a new production line for mineral feed. Founded in 1911 as an agricultural trading company, it has grown to become one of Austria's largest animal feed producers. In this customer story, Harald Schmalwieser, the General Manager of Solan, shares his experiences working with Dinnissen. He highlights, among other things, how effective liquid dosing has been a game changer for Solan, quadrupling production capacity and drastically reducing transportation times.

"WE HAVE QUADRUPLED OUR PRODUCTION CAPACITY, FROM 3 TO 12 TONS PER HOUR."

ForFarmers reduces cleaning costs and downtime with new Pegasus® mixers and coaters

ForFarmers is an international company specializing in animal feed for livestock farming. Recently, they replaced two of their Pegasus® mixers in their factory in Delden. In this article, Pieter Gorter, Project Manager at ForFarmers, shares why they chose Dinnissen mixers again and the advantages these new mixers bring, including reduced cleaning time and downtime, and how they contribute to a more sustainable mixing process. Discover how Dinnissen designed a custom-made Pegasus® mixer for ForFarmers.

"DINNISSEN THOUGHT ALONG WITH US FROM START TO FINISH, FOR EXAMPLE, THEY USED EXISTING DRAWINGS FOR THESE NEW MIXERS TO SAVE US COSTS IN THE ENGINEERING PHASE."

6x production increase for Nöll & Co thanks to new mixing line for all types of dry milk products

Nöll & Co is an expert in processing dry milk products, including protein concentrates, whey powder, cream powder, and caseinates. In 2014, Nöll & Co acquired the factory in Büren, but to stimulate their growth and continue providing customized solutions, they sought a partner who could upgrade their existing production line or design and install an entirely new one. In this customer story, CEO Michiel de Boer and team leader Ronny Kaß share their experience. Discover why they chose Dinnissen for hygiene and cleanability, how their daily production increased sixfold thanks to the new line and their positive experience with the support from Dinnissen’s engineers in achieving their output goals.

"PRODUCTION HAS GONE FROM 3-5 TONS PER DAY TO 30 TONS PER DAY. THAT'S A SIX-FOLD INCREASE IN TOTAL PRODUCTION."

How DSM reaches optimal food safety and hygiene of their infant nutrition premixes, with high-care mixing lines

DSM, a Dutch multinational in health, nutrition, and life science, approached Dinnissen in 2017 for the realization and total system integration of their high-care production facility for infant nutrition premixes in Poland. In this customer story, featuring Anton Vleeshouwers (Project Director) and Małgorzata Matysiak (Project Manager and current Site Manager in Buk), read about why DSM chose Dinnissen as a qualified partner, how they collaborated to optimize food safety, quality, and hygiene, how DSM reduced downtime with the hygienic design of their new mixing lines, and more about the project at the DSM factory in Poland.

"DINNISSEN FULLY UNDERSTOOD THE IMPORTANCE OF HYGIENE AND SAFETY REQUIREMENTS IN OUR INDUSTRY. THEY WENT THE EXTRA MILE BY PROVIDING US WITH ALL THE NECESSARY DOCUMENTATION, ALL ATEX DRAWINGS AND FULL TRACEABILITY."

Producing environment-friendly pig feed with Dinnissen mixers

Voergroep Zuid, a feed producer with more than 125 years of experience specializing in the production of pressed pig feed pellets, faced a growing concern in the late '80s about reducing phosphate emissions in the Netherlands. This led to the need for feed that was not only nutritious but also capable of reducing the phosphate emissions from pigs. Dinnissen developed a mixer that could spray essential substances such as phytase, enzymes, and fats onto the pig feed pellets, thereby improving the digestion of crude phosphorus and reducing phosphate emissions. Discover why, after 30 years, Voergroep Zuid once again chose Dinnissen for the replacement of their mixers.

"IN JUST UNDER TWO MINUTES, 500 KG OF PELLETS ARE MIXED, THE REQUIRED ENZYMES ARE APPLIED, AND THE PELLETS ARE GIVEN A FAT COATING."

Vobra produces Kibbles rich in healthy fats, without a greasy feel

Vobra, a family business with over 90 years of experience in animal nutrition, specializes in the production of healthy and tasty food for pets. The company started with livestock feed in 1932 and added dog and cat food to their range in 1970. In 1975, Vobra completely transitioned to producing kibble for dogs and cats. They have two production locations in the Netherlands, equipped with advanced machinery for hygienic, efficient, and sustainable production of pet food. Dinnissen has had a long-standing collaboration with Vobra, providing vacuum coaters for spraying essential nutrients onto the kibble, making it more nutritious and healthier. Discover how Dinnissen has contributed to the production of high-quality pet food.

"WE HAVE CHOSEN DINNISSEN AGAIN BECAUSE WE ARE VERY SATISFIED WITH THE VACUUM COATERS AND THE EXPERTISE OF DINNISSEN."

From 18 mixers to one Pegasus® Batch Mixer from Dinnissen

Holland Diervoeders, boasting over 200 years of experience in the animal feed industry, is part of Group Depre, a leading family-owned business in the West-European animal feed industry. Specializing in pet food for rodents and birds, Holland Diervoeders recently collaborated with LDL Bulkhandling to optimize their production process in Dordrecht. They successfully replaced 18 mixing machines with a single Pegasus® Batch Mixer from Dinnissen, resulting in significant energy savings, reduced maintenance, and space efficiency. This collaboration has led to a more efficient and sustainable production process for animal feed.

"DINNISSEN'S MIXERS HAVE A SHORT MIXING TIME AND ENSURE THAT NO RESIDUES REMAIN IN THE MACHINE AFTER THE MIXING PROCESS. AS A RESULT, THE MIXER DOES NOT NEED TO BE CLEANED AFTER EACH BATCH."

Dinnissen and Vitelia - decades of collaboration and innovation

The long-standing collaboration between Dinnissen, a leading machinery manufacturer, and Vitelia, an animal feed cooperative, has led to continuous development and innovation in the livestock feed industry. In this interview, Stefan Kuijpers, director of Vitelia, Mathieu Maes, former director and owner of Dinnissen, and Wouter Kuijpers, operational director and co-owner of Dinnissen, share their stories about this successful partnership. They discuss how the livestock feed industry has evolved and how Dinnissen provided innovative solutions, such as an automatic sieve changer and improved mixing processes.

"OUR COLLABORATION WITH DINNISSEN IS BASED ON MUTUAL RESPECT AND TRUST. WE CHALLENGE EACH OTHER TO CONTINUOUSLY INNOVATE AND IMPROVE."

Südstärke and Dinnissen: partnership in innovation and reliability

Südstärke is a leading potato starch producer with facilities in Sünching and Schrobenhausen. They process approximately 600,000 tons of potatoes annually into 150,000 tons of starch, which is used in various sectors including the food industry, paper industry, chemical industry, and animal feed. The company recently collaborated with Dinnissen to implement sieving machines suitable for processing potato starch with varying moisture content. This collaboration has led to more efficient and higher quality processing methods. Both companies share values of reliability and innovation, which enhance their successful partnership and enable them to explore new technologies for future improvements.

"THE EASE AND SAFETY WITH WHICH THE SIEVE BASKET CAN BE CHANGED WERE DECISIVE FACTORS IN OUR CHOICE FOR A DINNISSEN SIFTING MACHINE."

Downtime is a thing of the past with new powder dosing installation

AAK Rotterdam is a key link in AAK's global production chain, specializing in vegetable oils. The company focuses on refining these oils, ensuring the highest food safety standards, especially for clients in the baby food industry. In this process, powders are added to remove impurities, requiring precise dosing. AAK Rotterdam opted for a Dinnissen solution to enhance their powder dosing and meet stringent hygiene standards. This custom-designed installation has led to significant benefits, including reduced dust emissions, decreased overdosing, and consistent product quality.

"WHAT REALLY MAKES DINNISSEN UNIQUE, IS THE PRELIMINARY WORK. YOU CAN LITERALLY COUNT EVERY BOLT AND NUT IN THE DRAWING."

Read more articles:

Frans Bakker on sustainability in the process industry

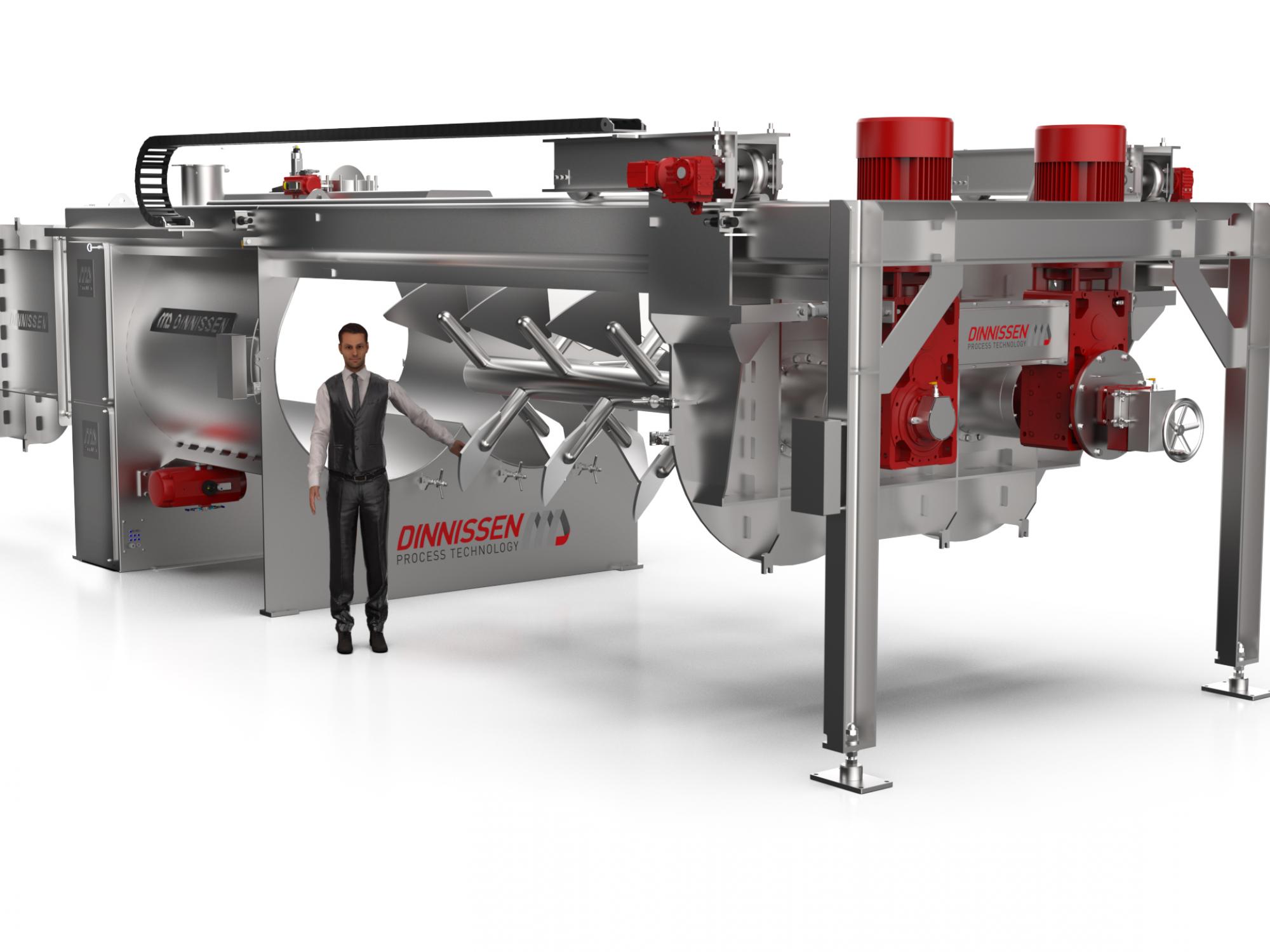

7 key benefits of our largest-ever mixer with extractable shafts

'No-touch' process equipment improves food safety

We are proud that these companies rely on Dinnissen

Do you have a question about your process?

- Over 75 years of experience in your industry as a system integrator

- Everything in-house: engineering, production, testing, installation, control, and service

- Always a tailor-made solution for your entire process

STAY AUTOMATICALLY UPDATED?

Subscribe to our newsletter and automatically receive information about the latest innovations, news about trade shows, and other developments at Dinnissen Process Technology.