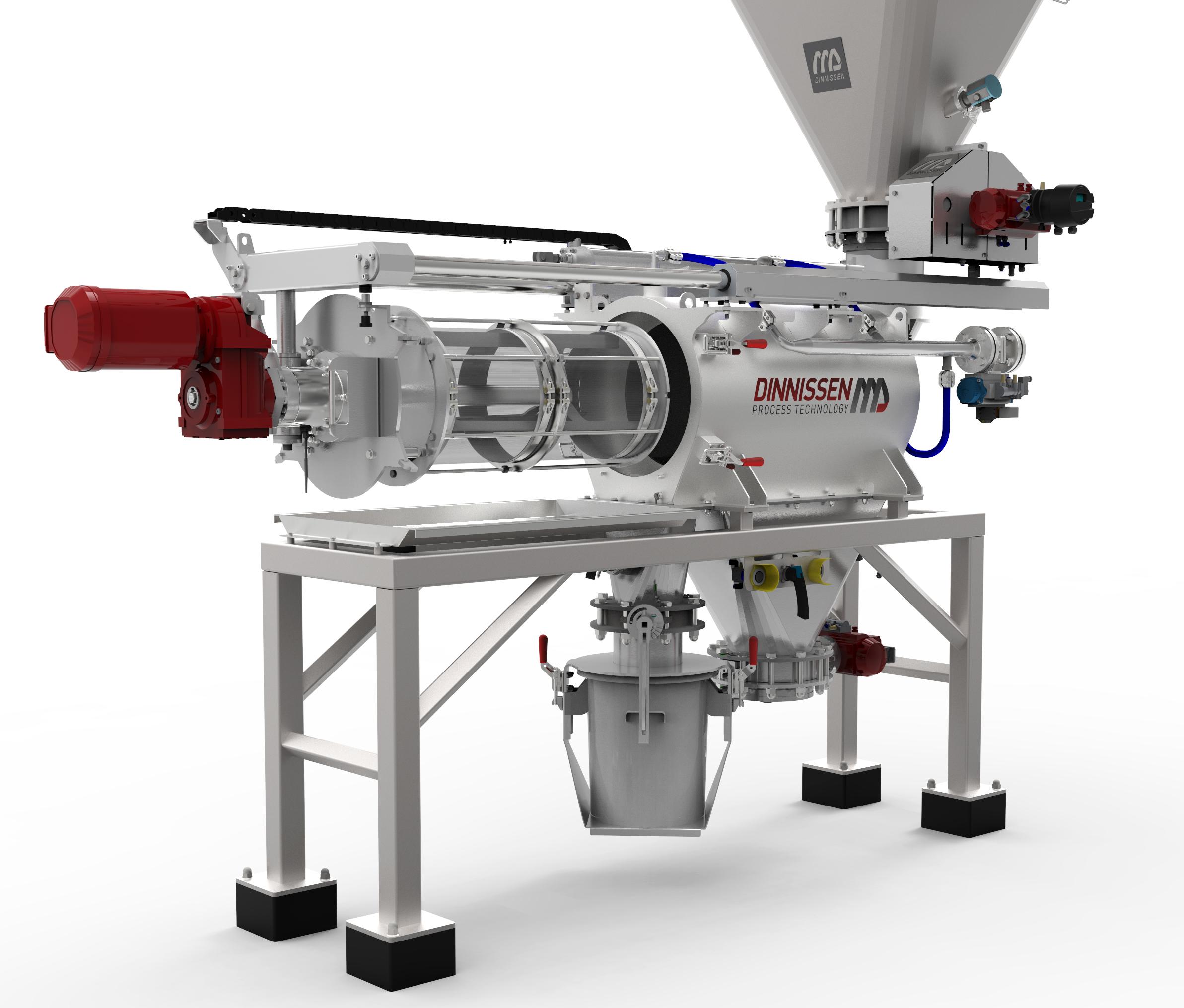

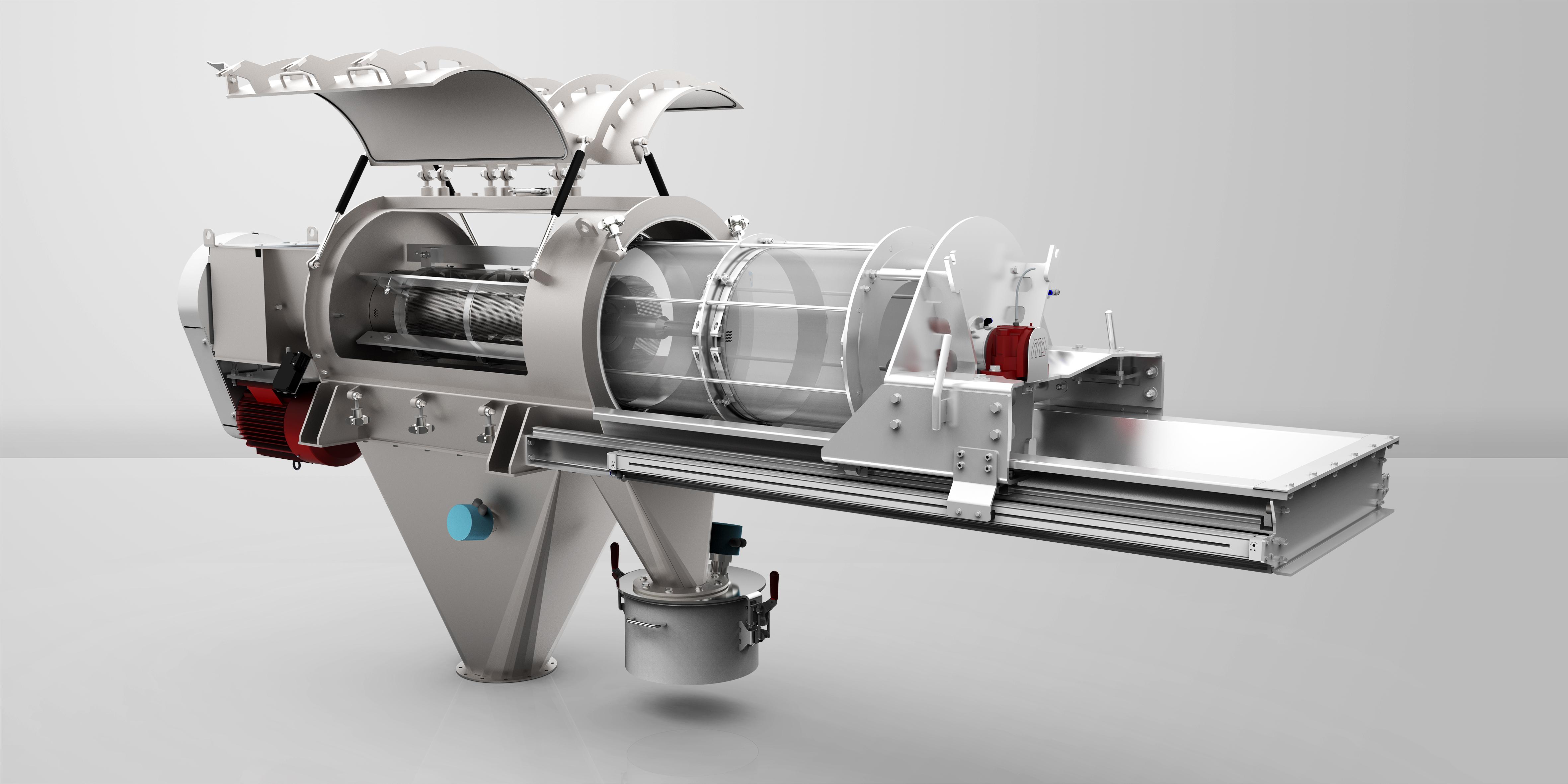

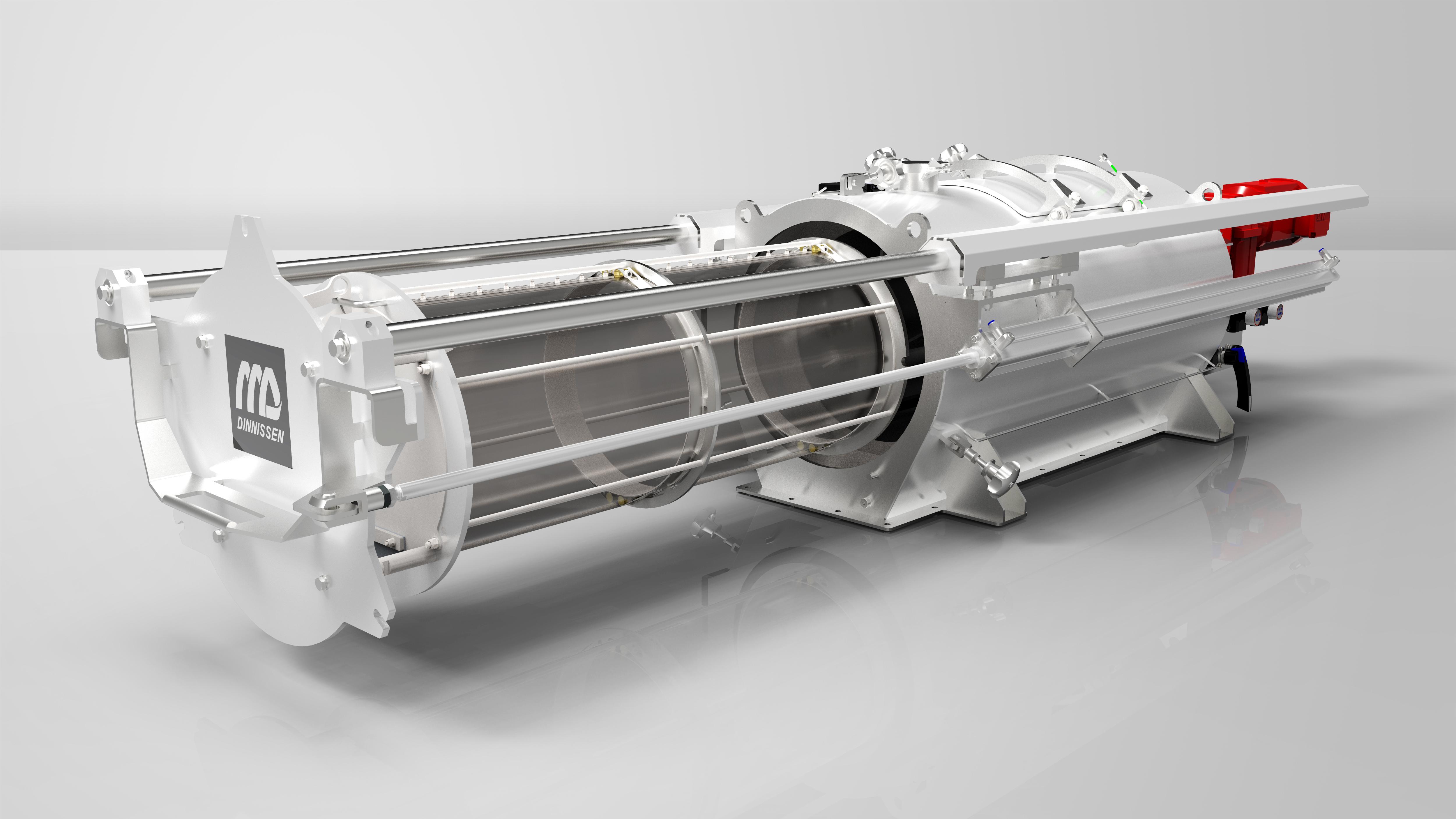

Integration into your existing conveying system - Easy to remove residual product - Special infeed system

Depending on the application, Dinnissen offers sifting systems with capacities up to 30 tons/hour and mesh openings of 250 µ to 2000 . In these screening systems, the product is introduced through a special input system at the top, where rotating paddles set the product in motion. The centrifugal forces spread the product very evenly over the entire screen surface, whereby the larger product parts are guided to a separate outlet of the machine. Here the non-sifted residual product can be removed through the easy-access hatch.

Depending on the type of product and the required size of the screen surface, we will deliver a solution that fully meets the desired capacity and level of integration into your existing conveyor system.

Do you want to know how you can sift materials more efficiently and productively? And would you also like to know about integration of a centrifugal sifter into your process? Feel free to contact one of our specialists via [email protected] or call +31774673555, without any obligation.