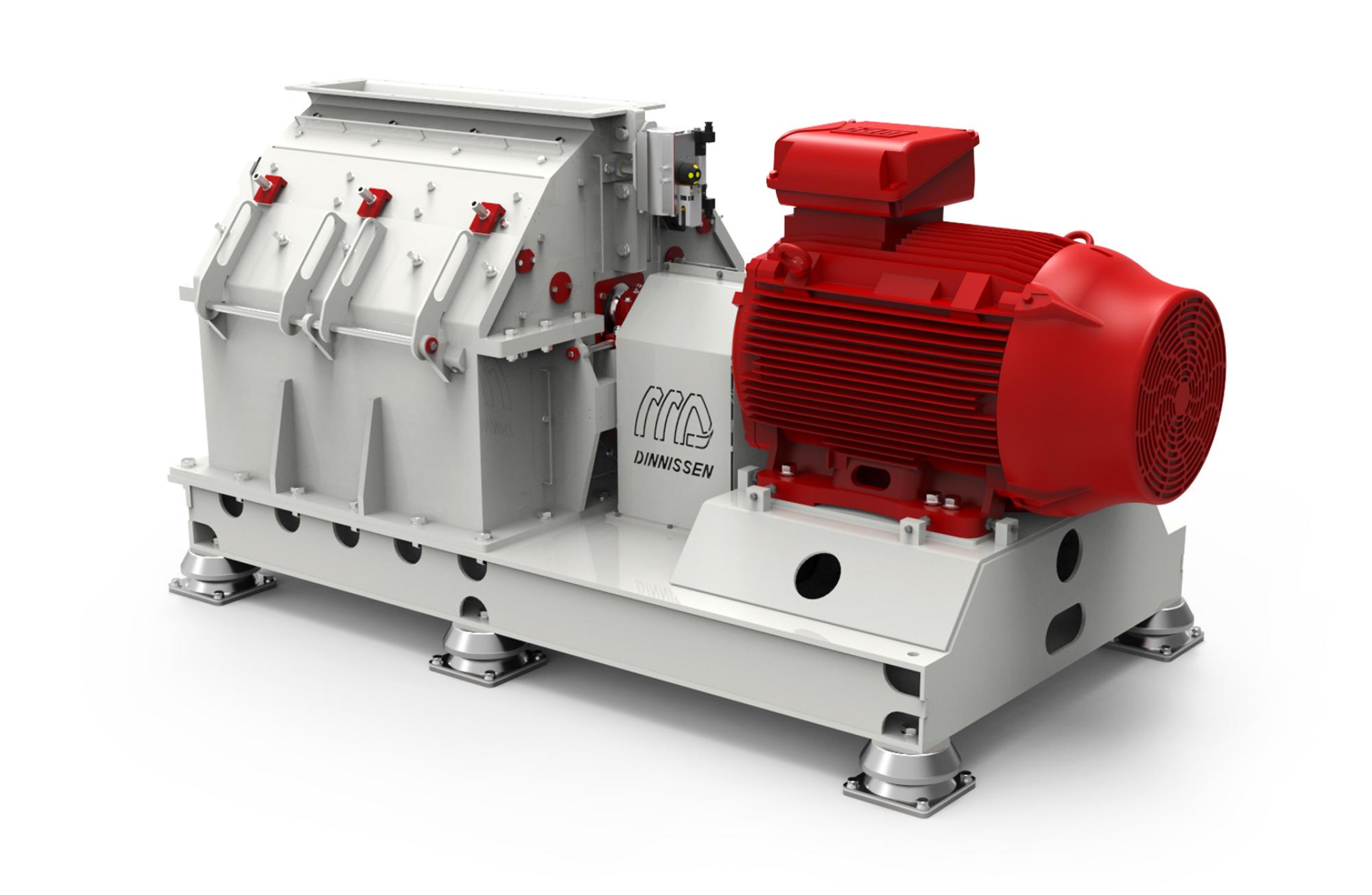

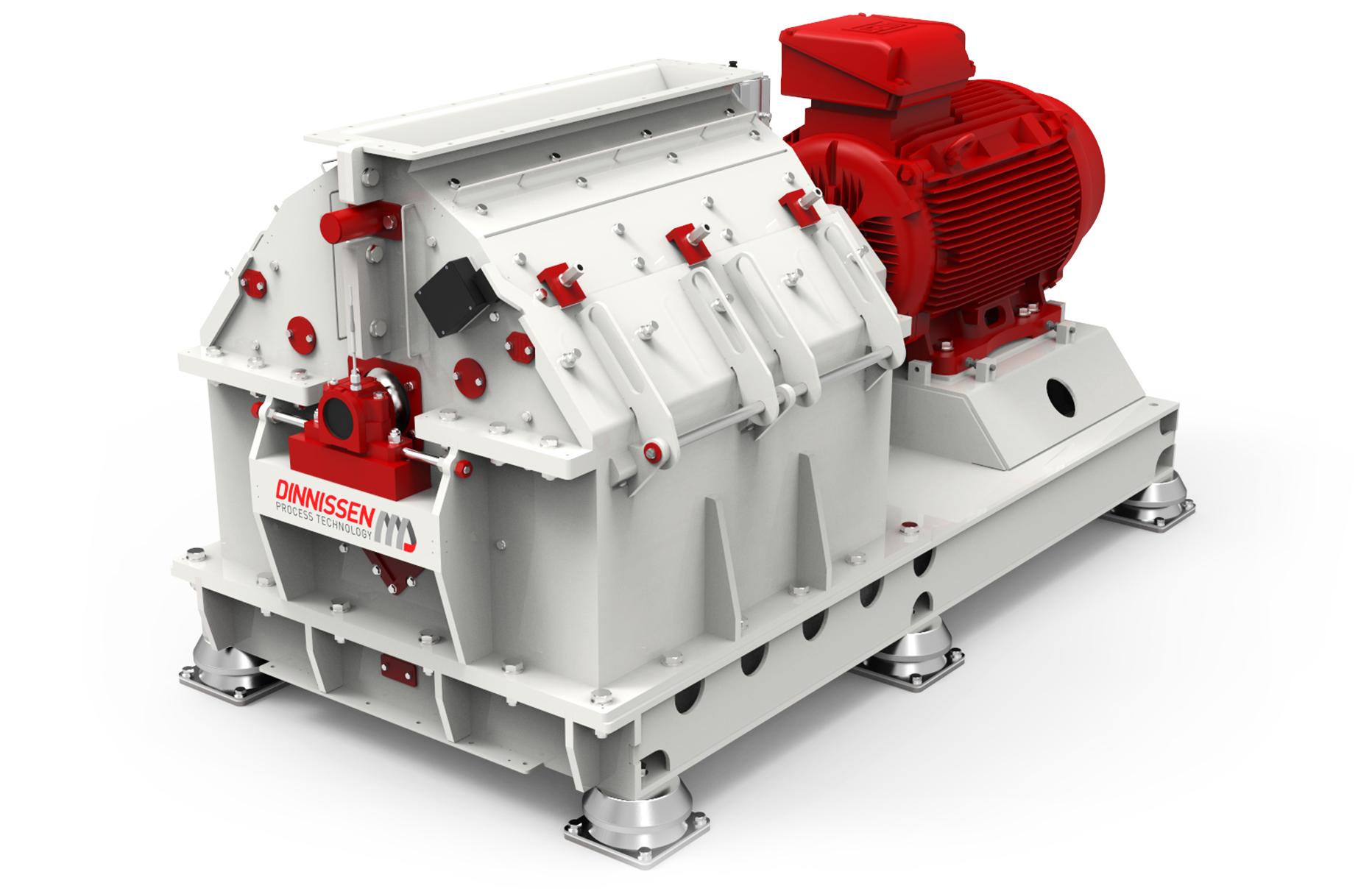

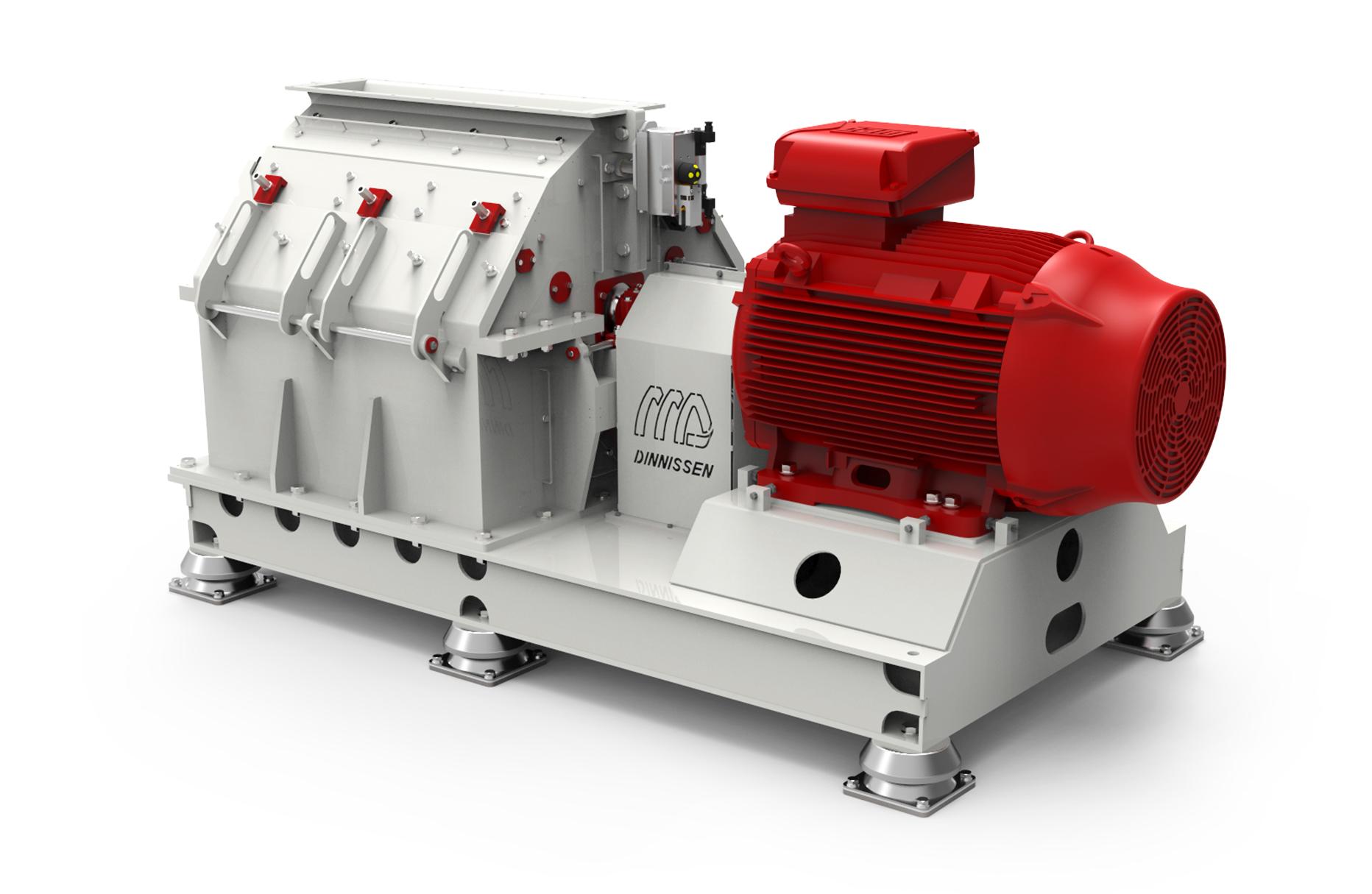

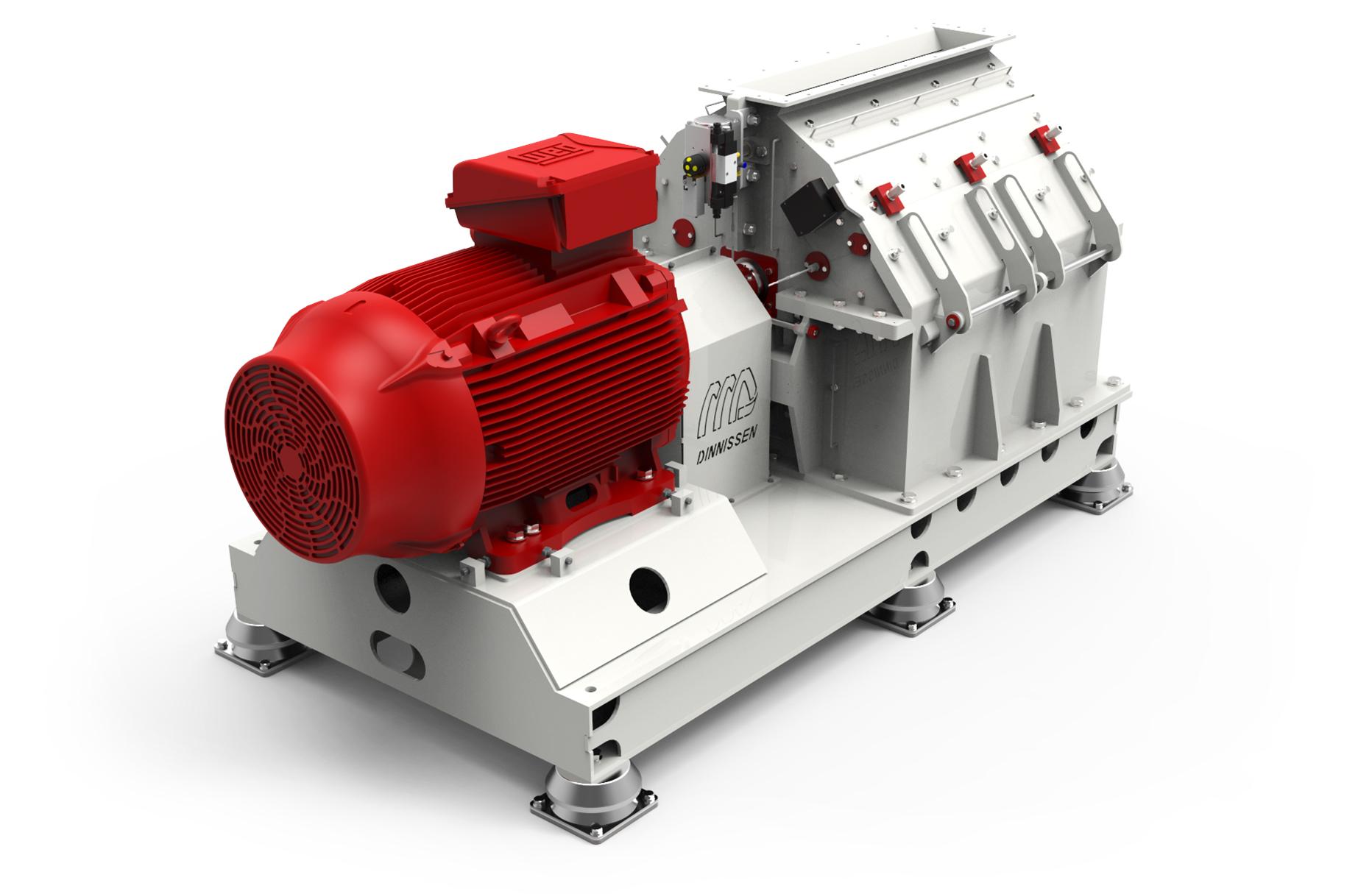

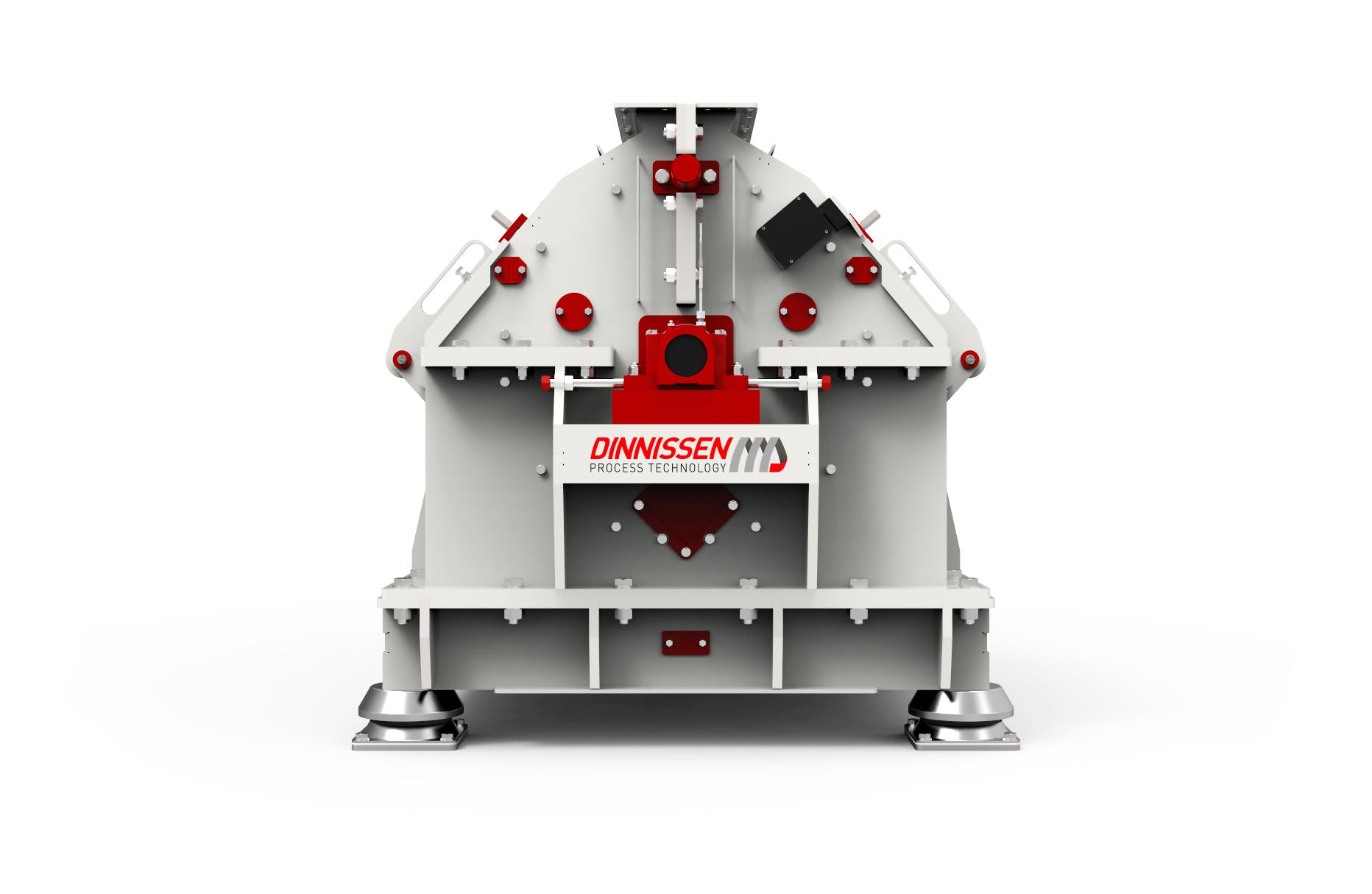

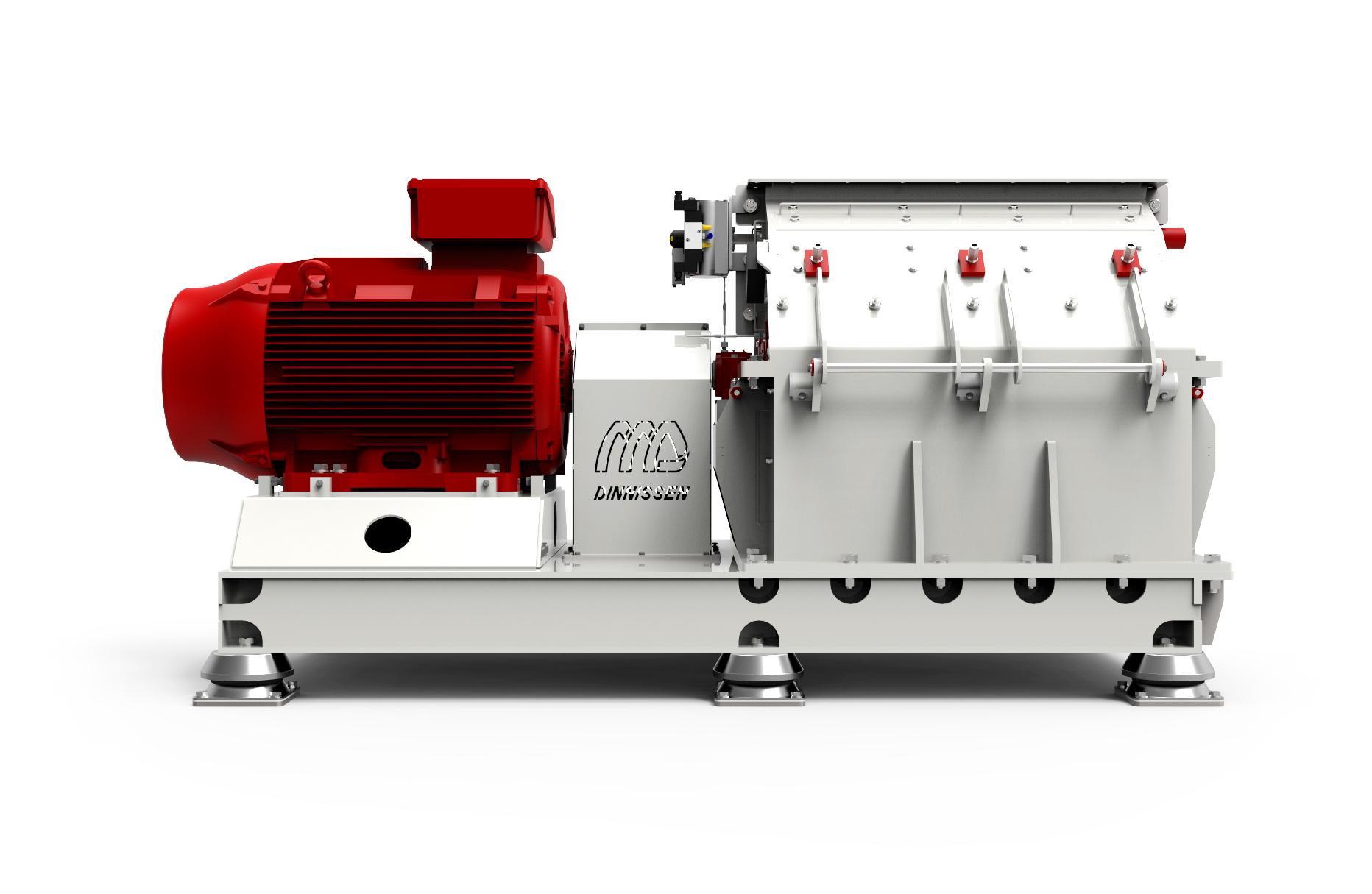

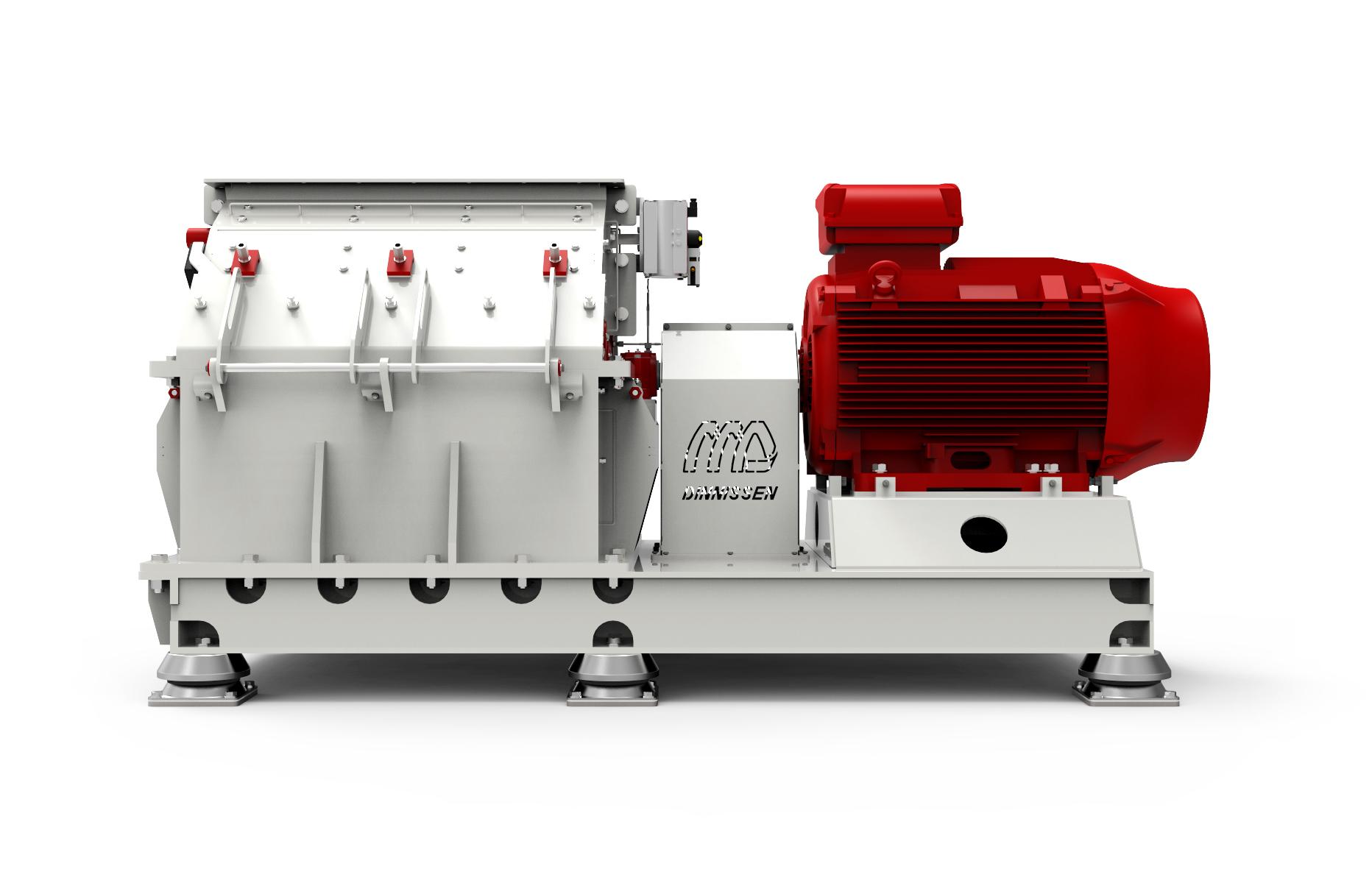

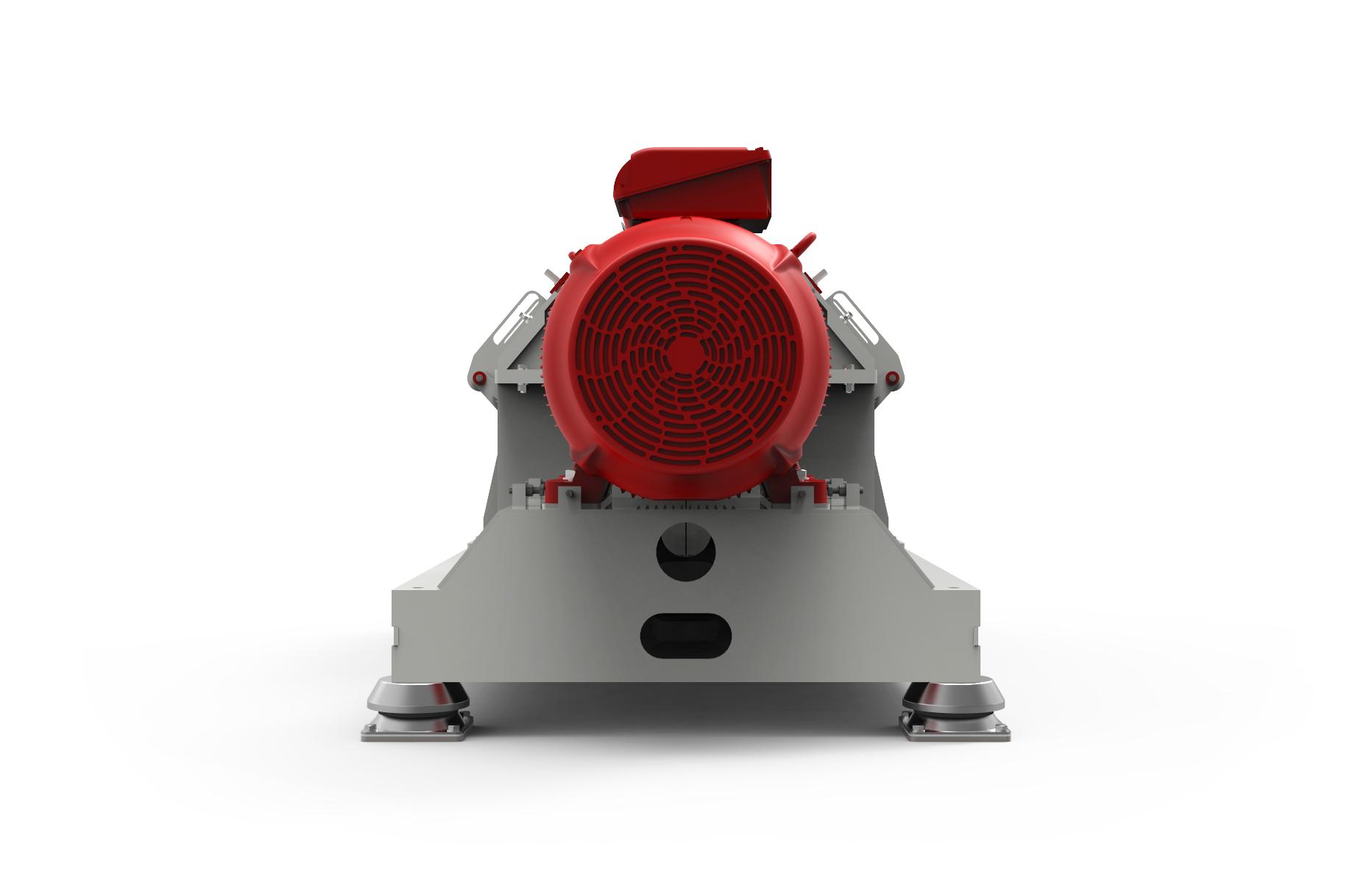

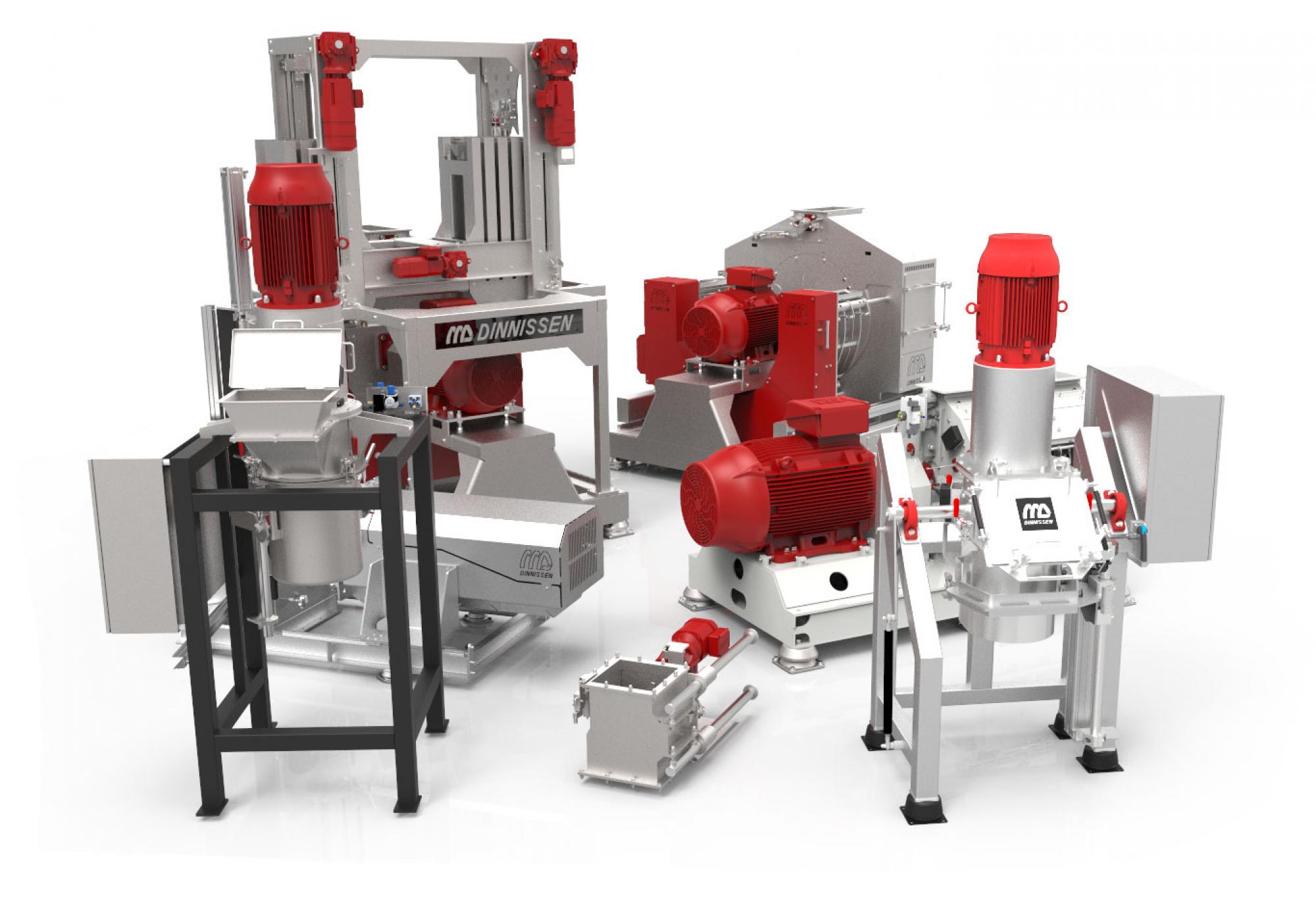

Hamex® hammer mills have been used successfully for decades by manufacturers in various sectors. It is a reliable solution for grinding soft to medium-hard products, such as grains, sugars and minerals with finenesses from 150 microns to approximately 3 mm. All Hamex® hammer mills are designed as follows, for efficiency and reliability:

- Proven robust construction: guaranteed long life.

- Good accessibility: wear parts can be replaced quickly.

- Variable direction of rotation to spread wear.

- Production, quality control and testing: everything is done in-house.

In addition, this hammer mill can be equipped with frequency control, with which the rotor speed can be accurately adjusted to the desired end result. You can easily switch between fine grinding or a coarse grinding structure. Another option is a specially developed airflow system, with which the passage of particles with the correct fineness is controlled quickly and efficiently. This increases the capacity and saves on energy consumption.

Read on to discover how the Hamex® Hammer Mill works. For more information, please contact one of our specialists by sending an email to [email protected] or calling +31774673555, without any obligation.