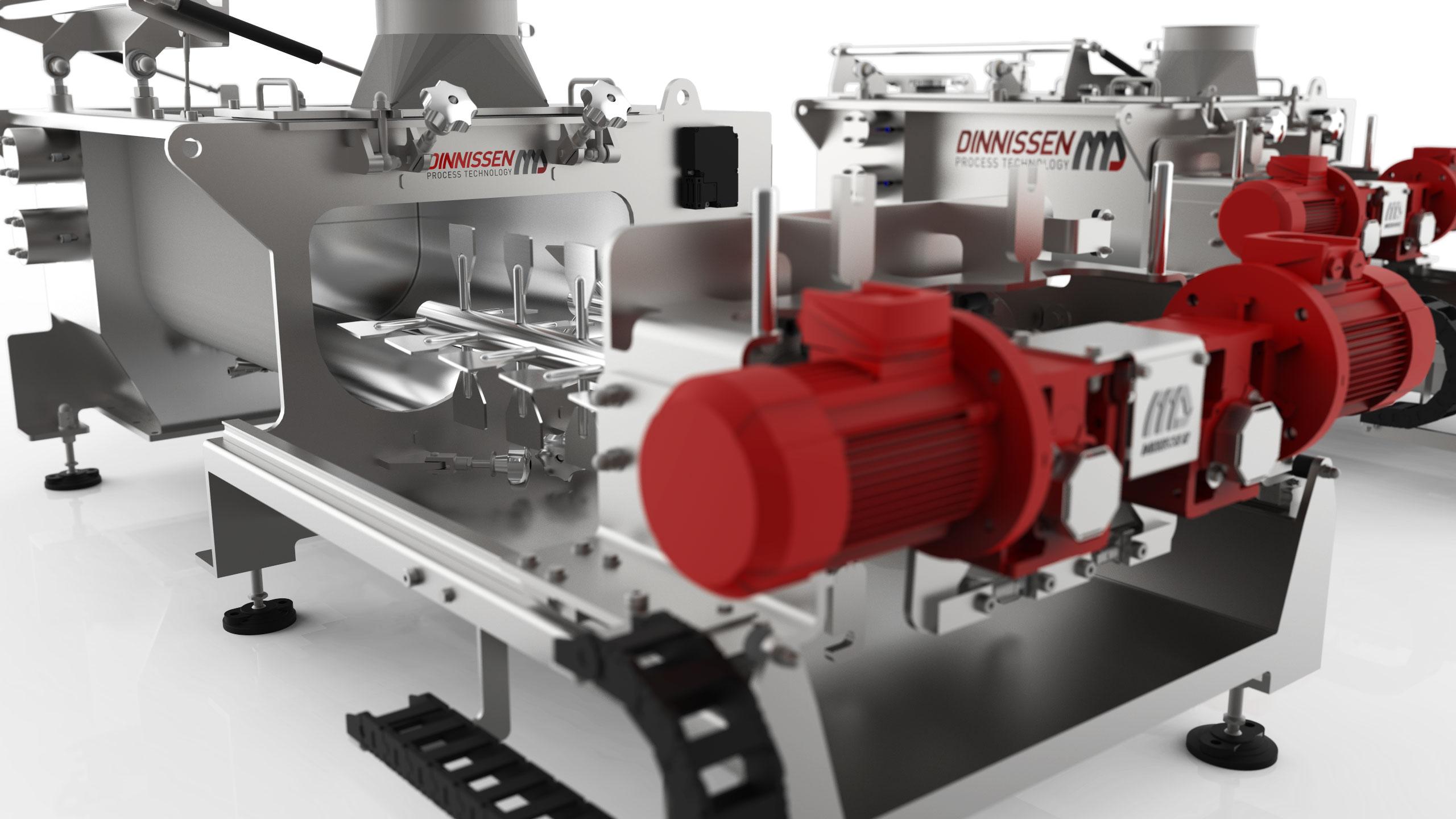

Double axis - Preheating possible - Hatches for inspection and maintenance

With the Pegasus® Conditioner you can mix different types of bulk goods, such as powders, steam, water and fats. The intensive and continuous mixing process ensures an optimal and homogeneous end product. If desired, you can also heat the product, for example as pre-treatment or for salmonella control.

The horizontal paddles are positioned at a specific angle in the mixing chamber of the double-axle conditioner. This special paddle mounting angle on the axles ensures optimal mixing. You can manually adjust the product processing time and the fill quantity to suit requirements. Maintenance and inspection can be handled quickly through the easily accessed and secured hatches. This contributes to guaranteeing continuity of your production process.

Would you like to know how the Dinnissen Pegasus® mixer could add value to your process? Feel free to contact one of our specialists by sending an email to [email protected] or calling +31774673555, without any obligation.