Lower boiling point due to vacuum - Multiple layers simultaneously in any desired dosage

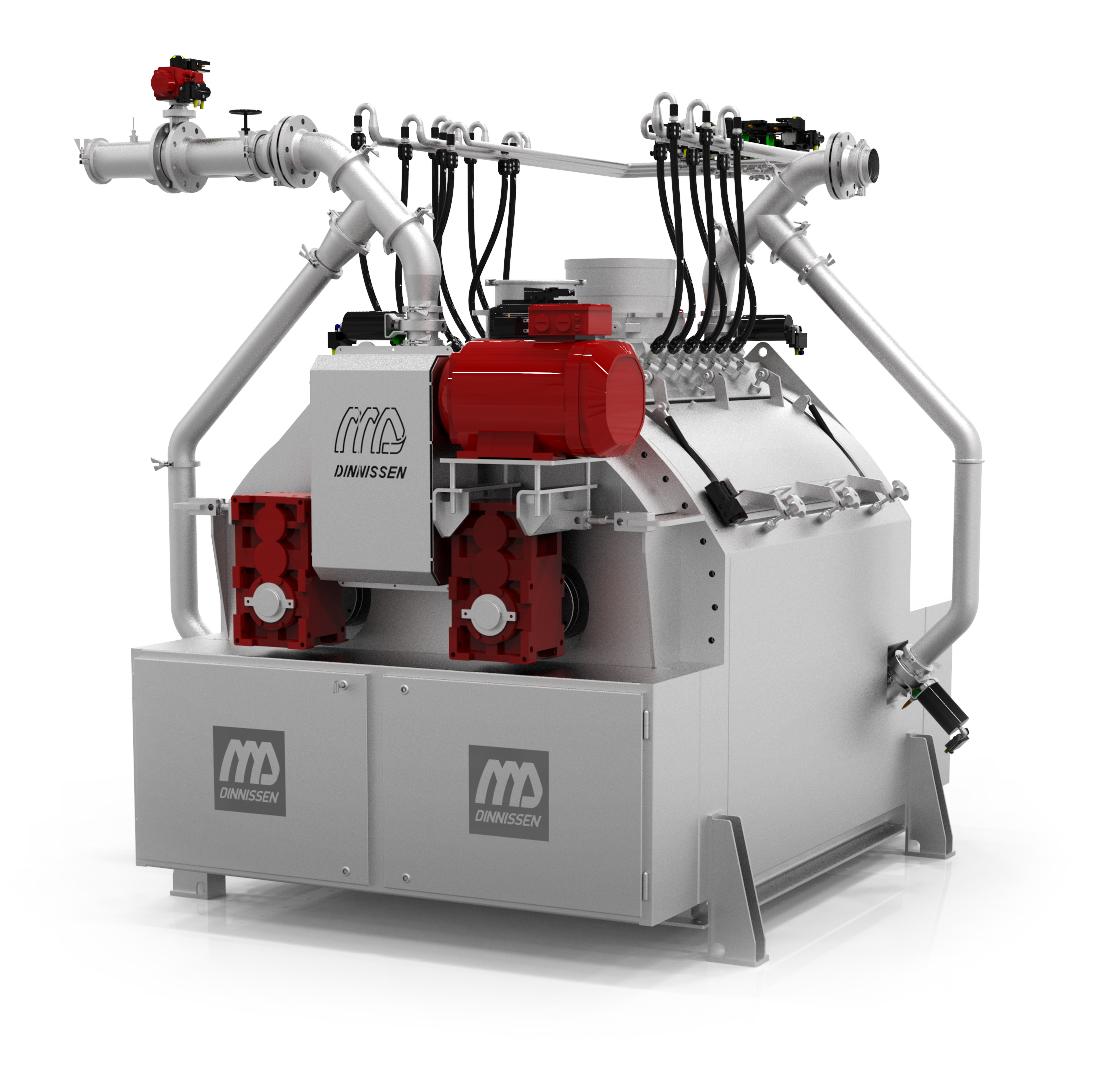

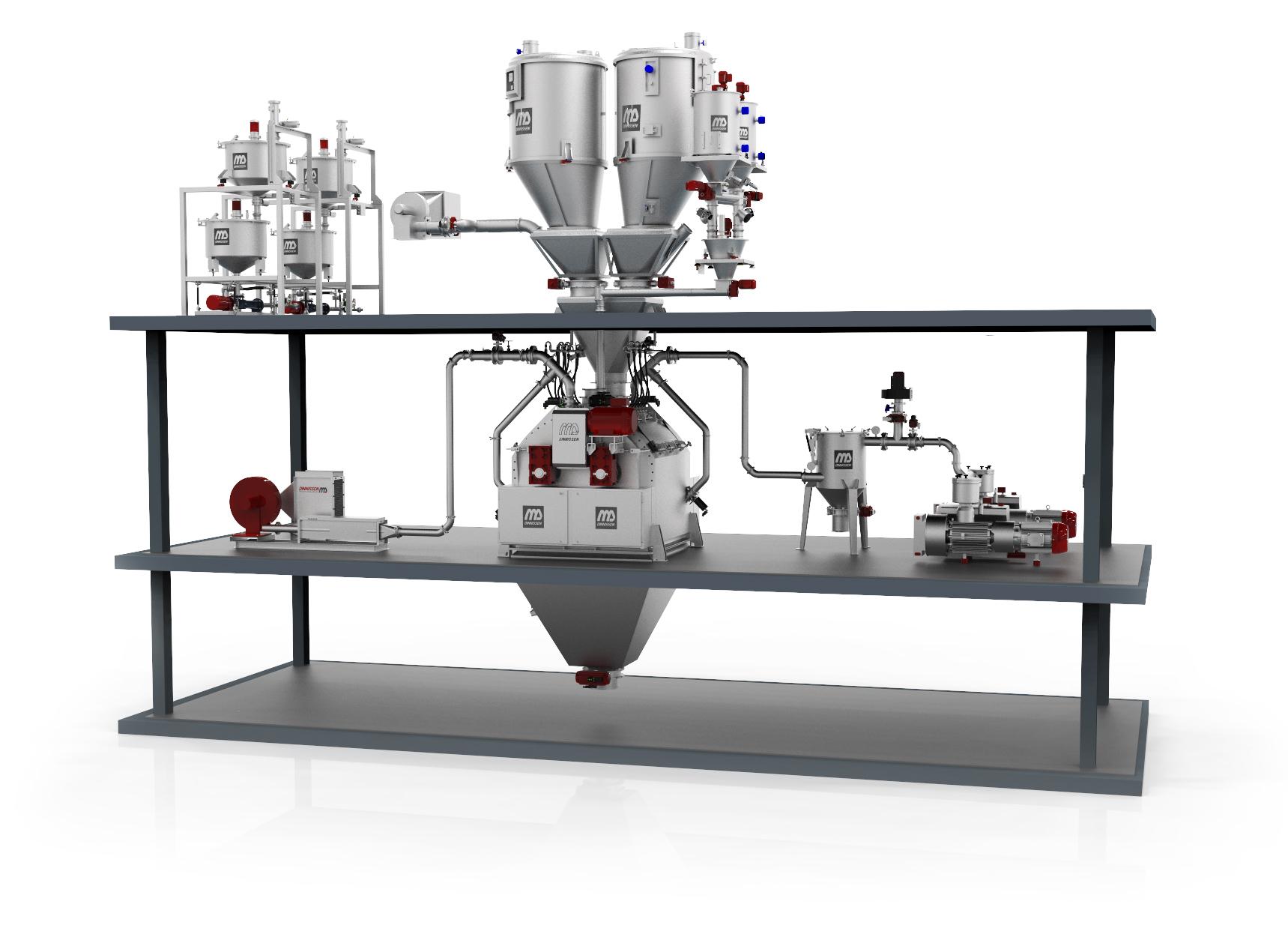

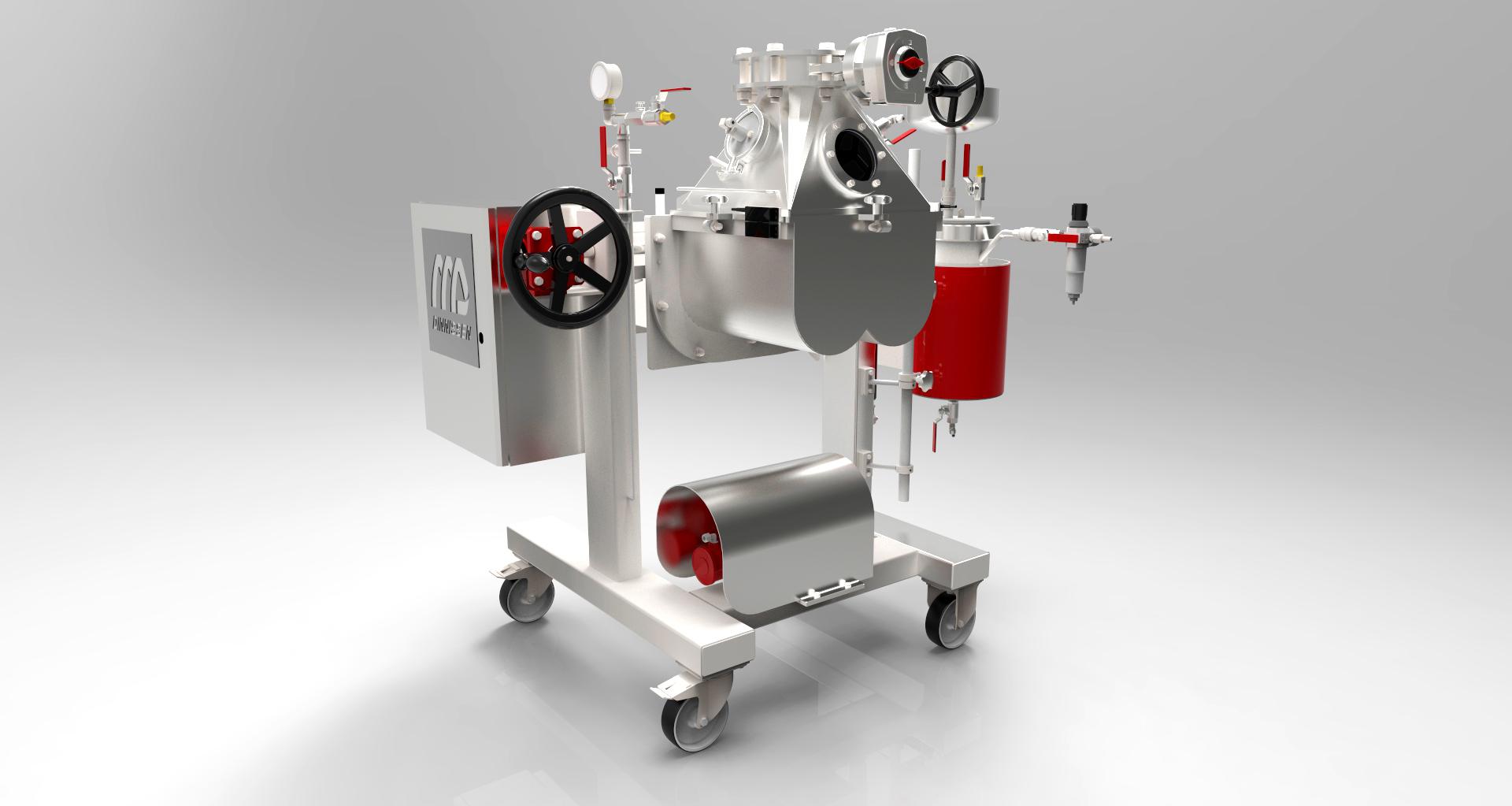

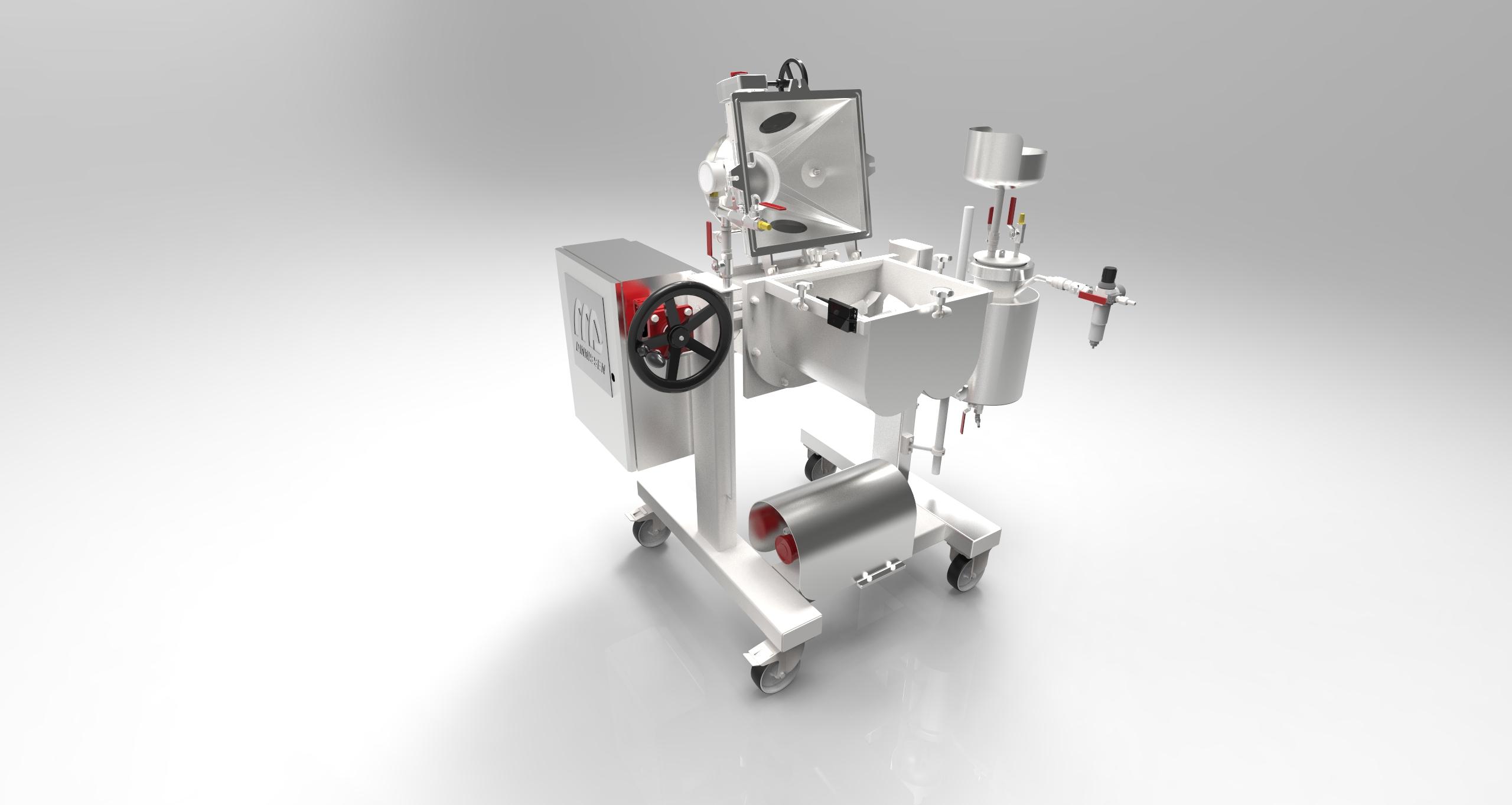

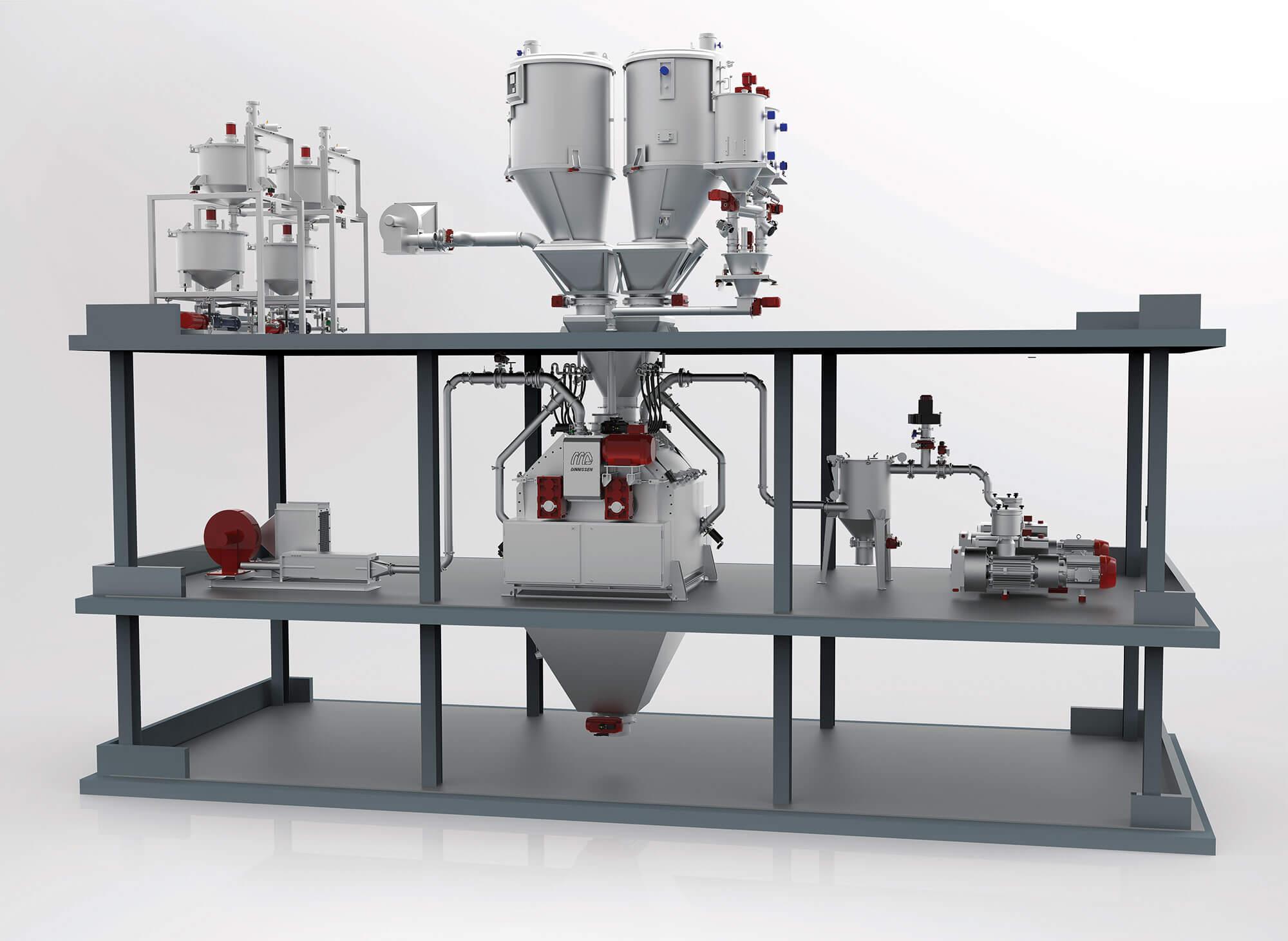

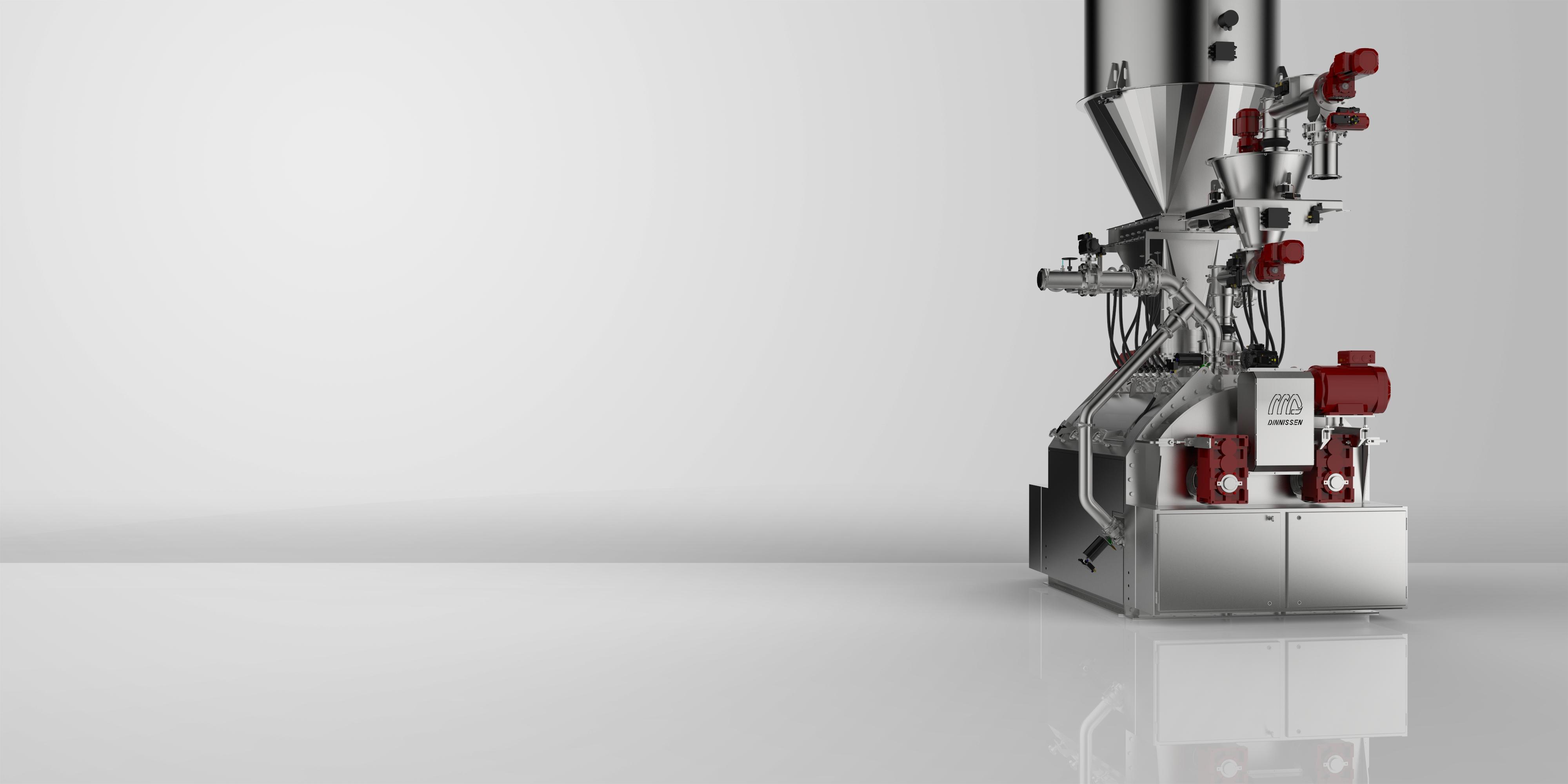

With this Dinnissen invention you can develop completely new products or tap into a fresh market potential. This machine’s adjustable vacuum permits application of exactly the right amount of powder or liquid to any porous product, and the vacuum ensures deep penetration into the product. Consider adding aromas, oils, vitamins, minerals and enzymes to granular materials and extruded products such as cereals. It is even possible to simultaneously apply multiple layers of powders or liquids in any desired dosage, or to completely coat the product with a preservative, protective or decorative coating.

Drying while retaining essential properties

The reduced boiling point of raw materials in a vacuum environment is yet another advantage. This means that moisture can also be extracted from specific products, while completely preserving taste, colour and functional substances such as vitamins, minerals, flavourings and enzymes. As the inventor of vacuum coating, Dinnissen has been the absolute market leader in this field for more than 25 years.

Would you like to know how our Pegasus® Vacuum Coaters could add value for your process? Feel free to contact one of our specialists by sending an email to [email protected] or calling +31774673555, without any obligation.