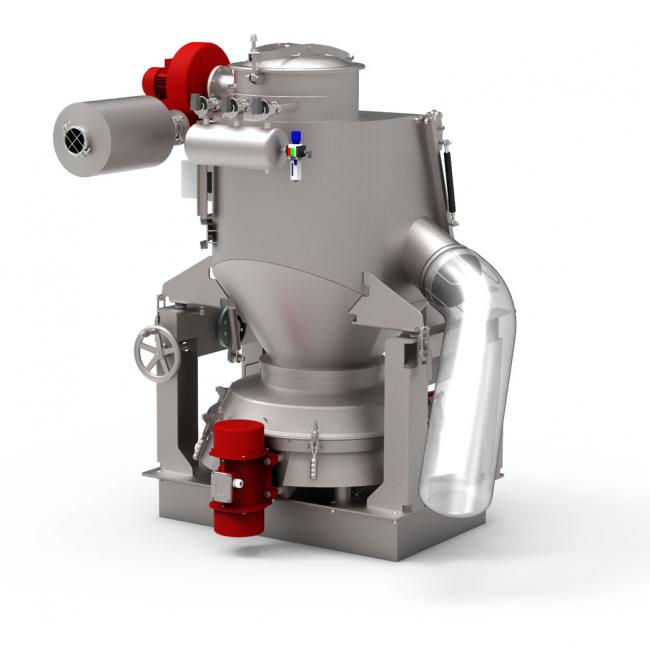

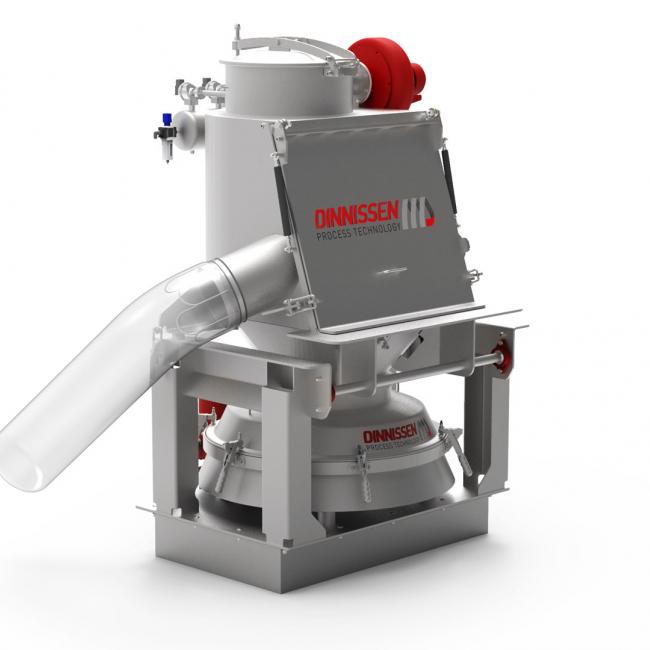

New Dima® Bag Emptier with tiltable body

New Dima® Bag Emptier with tiltable body

New Dima® Bag Emptier with tiltable body

Why a tiltable Dima® Bag Emptier can improve your product intake processes:

- Less time needed to clean, inspect or replace parts

- It is a very safe way for efficient bag emptying

- Designed with operator ergonomics in mind

- Robust quality, this Dima® will last a long time

How this Bag Emptier helps you deal with strict hygienic rules and regulations

By designing a tiltable body, this Dima® can be opened for easy access to areas that are normally difficult to reach. This speeds up cleaning, inspection and part replacements. Opening can be done by a single operator, simply by turning a handwheel. It’s almost completely effortless. And air ventilation ensures that no dust will escape.

Features of this Dima Bag Emptier

- Easy-to-clean and inspect

- Perfectly safe for both operators and the environment

- Robust quality, built to last

- Designed, built and tested in-house

Would you like to know how you can use a tiltable DIMA® Bag Emptier to add value to your process? Please feel free to me or one of my colleagues. We’re happy to answer your questions.

WE'RE PROUD THE BE TRUSTED BY THE BEST

Over 70 years of experience in process innovation

Dinnissen Process Technology has been developing machines, complete production lines, and customized solutions for the food, feed, pet food, and chemical industries since 1948. The main focus is on the efficient handling and processing of powders, particles, and granulates. From product intake, conveying and handling, feeding and weighing, mixing and processing, milling and grinding, sifting and packaging: System integrator Dinnissen automates, optimizes, and innovates entire production processes with tailor-made solutions.

For many years Dinnissen has been known on an international scale for its capacity to convert technical innovation into value-adding solutions. Dozens of innovations have been successfully adopted by the world's largest producers in the feed, food, pet food, and chemical sectors.

Examples of such groundbreaking innovations are the vacuum core coating process, the lean gravity mixing lines, and the hammer mill with an automatic sieve changing system. Thanks to these and other technical breakthroughs, Dinnissen has become the global market leader in process technology for powders, particles, and granules in various industries.