Key features, options, and models

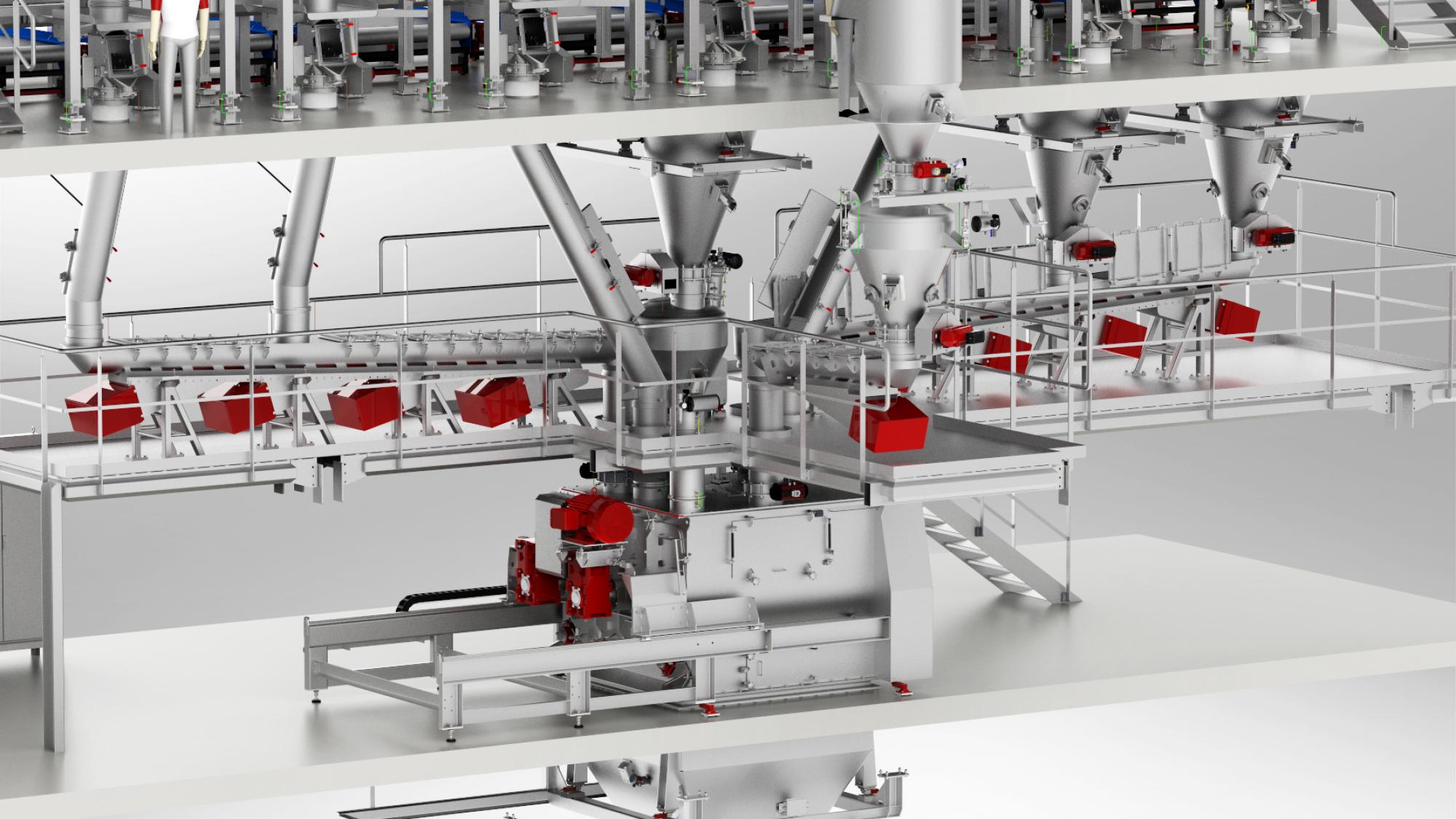

Dinnissen offers various solutions for pneumatic conveying. We have systems that work with air pressure, but also solutions with gas. The product can be temporarily diluted with air or gas, allowing high transport speeds to be achieved. In addition, you can move the product as a whole, using high-pressure locks or transmitting barrel transport.

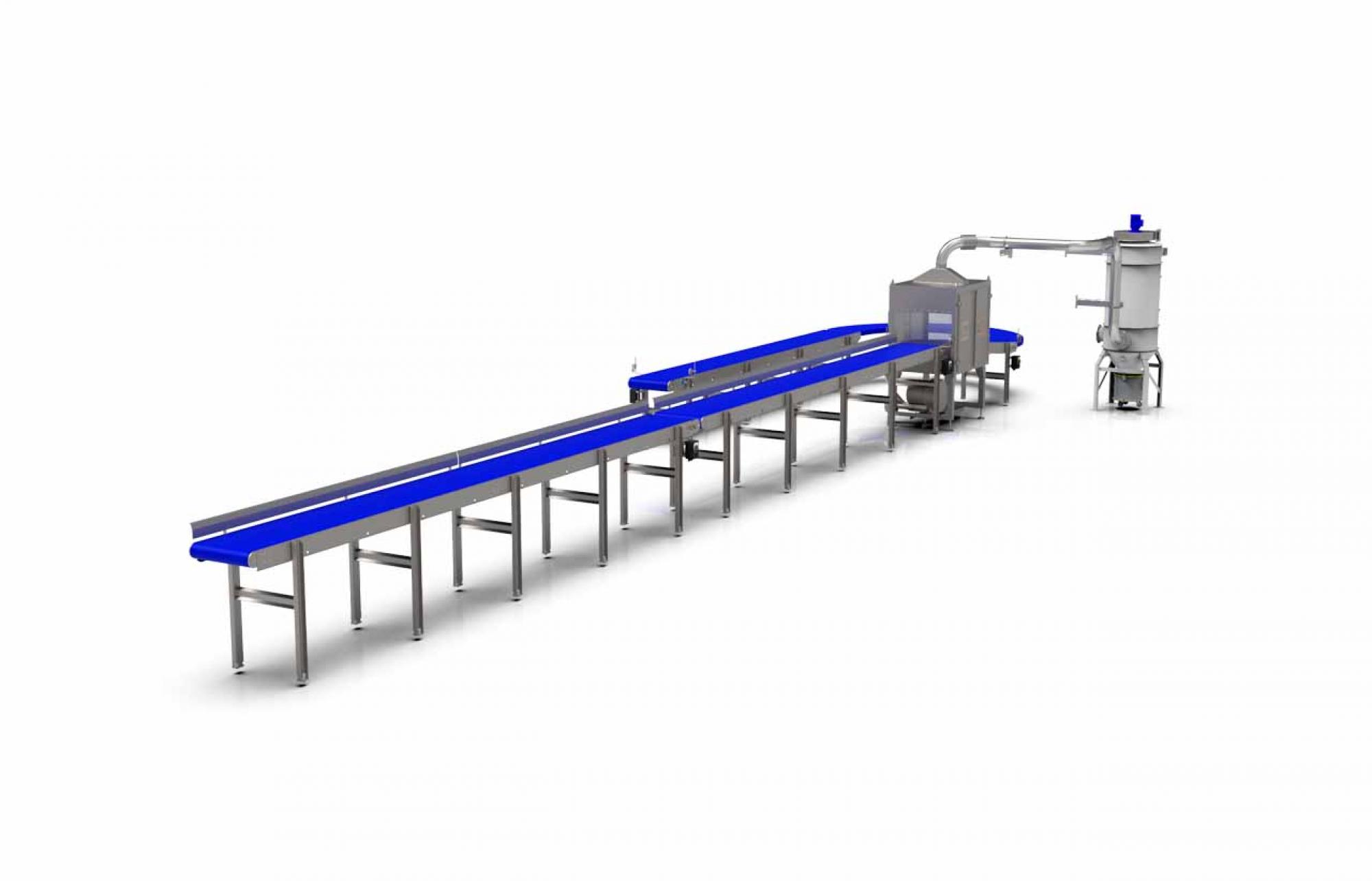

In addition to the above solutions, Dinnissen has developed a special slow-flow transport system, suitable for continuous production processes with strict hygiene requirements. The focus here is on fast and thorough cleaning, including ultra-dustproof sealing of the transport system. As the ratio of loading to conveying air is optimal, relatively low transport speeds occur. This makes the system particularly suitable for breakage-sensitive, abrasive and greasy raw materials, such as milk powder, sugar, sand, chalk, milk, and cocoa.

Slow-flow transport system

Within the slow flow concept, an extremely compact receiver system is sufficient, which is quick and easy to clean and can be easily integrated into new and existing situations. Moreover, it has low gas and energy consumption, which makes a compact air handling system and a small air filter sufficient.

Depending on your preferences, the slow-flow transport system can be automatically cleaned and made ultra-dustproof. It is also possible to increase capacity. In addition, high-precision measuring and weighing equipment can be integrated, you can create under- or overpressure, choose inflatable seals or automatic cleaning by air. As a source for generating the transport medium, a medium pressure blower or compressor is often used, with an overpressure of 0.2 to 0.5 bar.

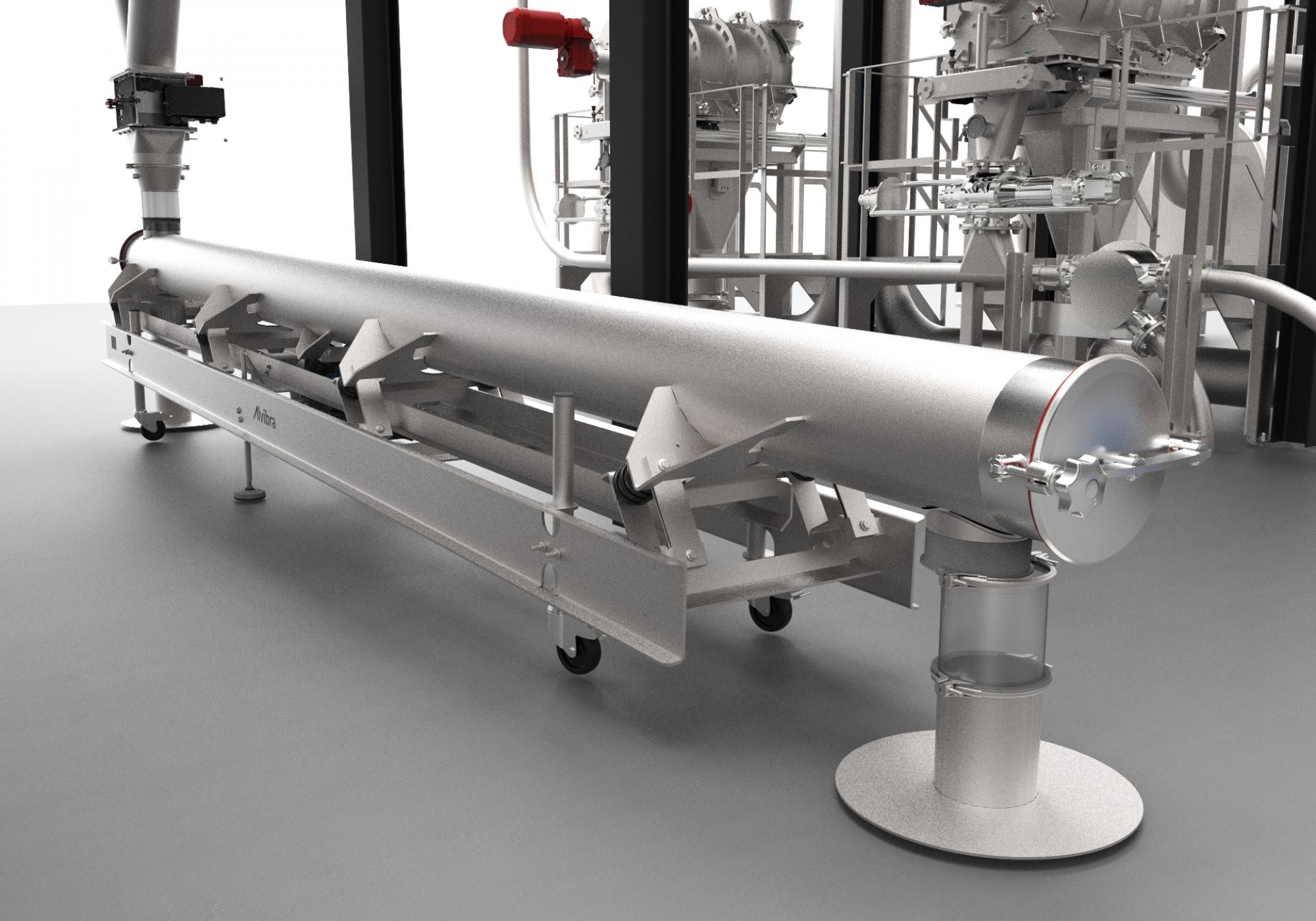

Closed-loop-transport

In addition to the above options, we also have closed-loop transport systems. As the name suggests, it’s a closed-loop system, in which the transport medium air is replaced by an inert gas such as nitrogen. This creates an explosion- and oxidation-free transport solution. To keep gas costs at a minimum, the system is equipped with an innovative gas recovery system.