Key features, options, and versions

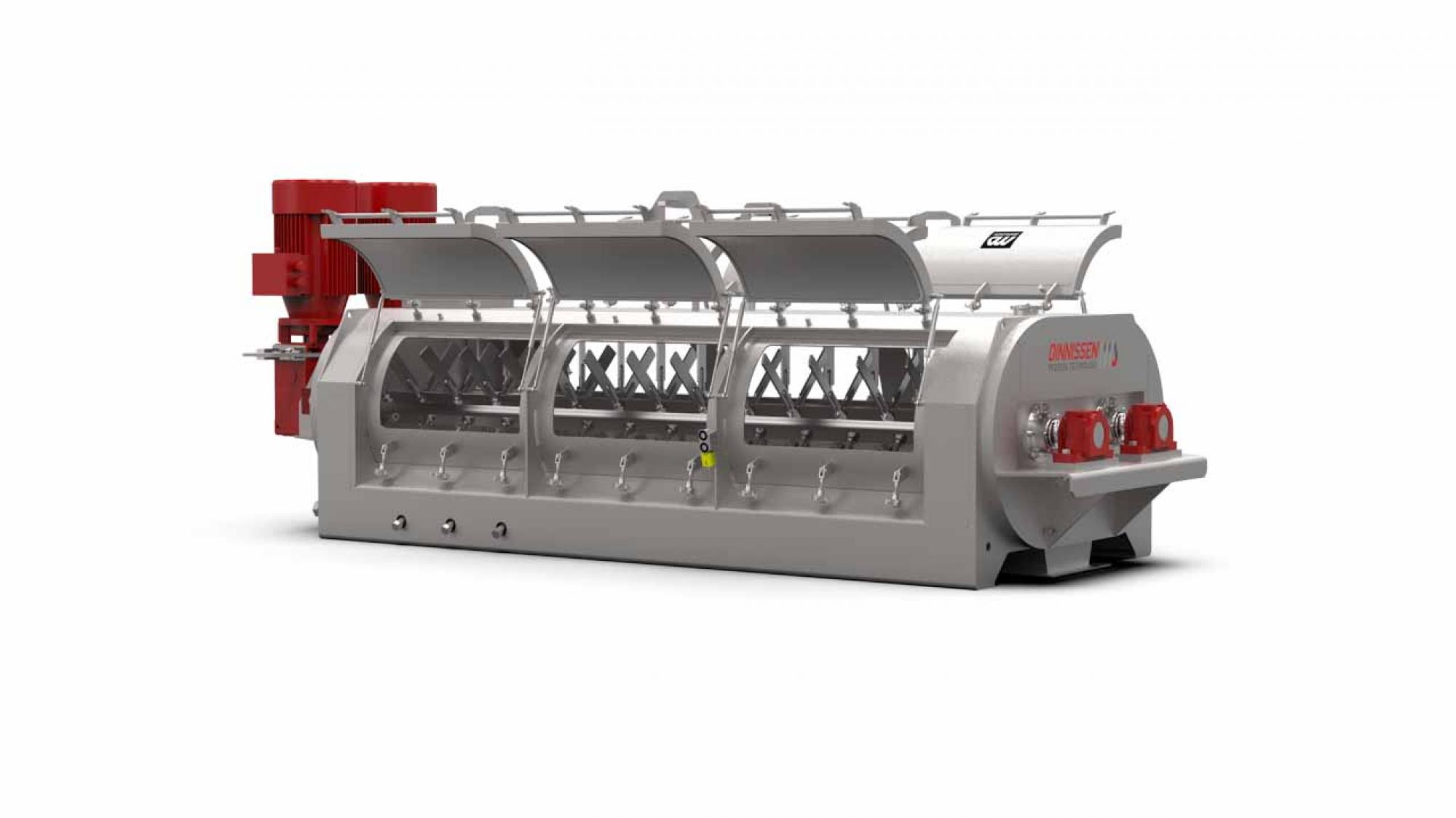

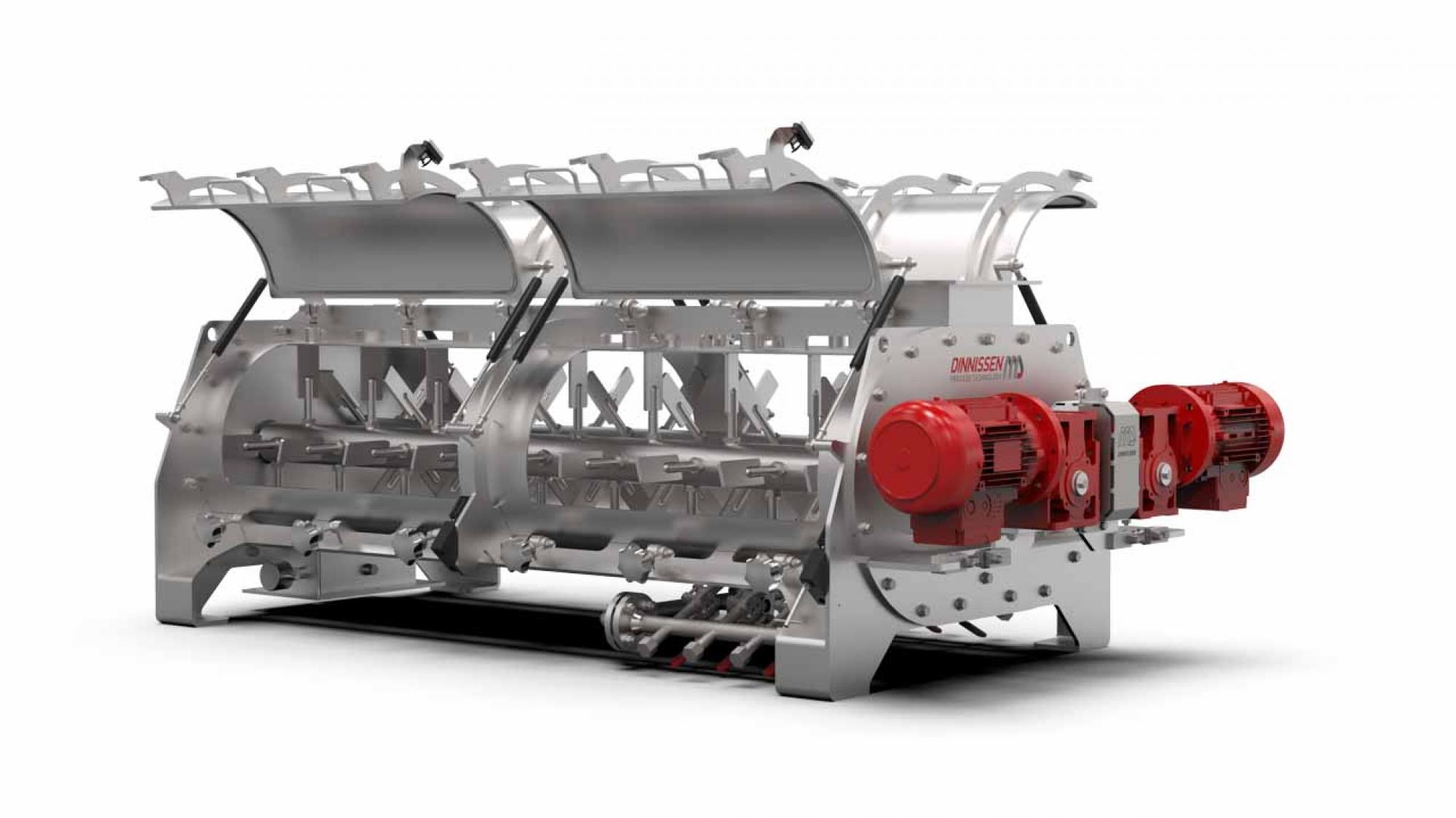

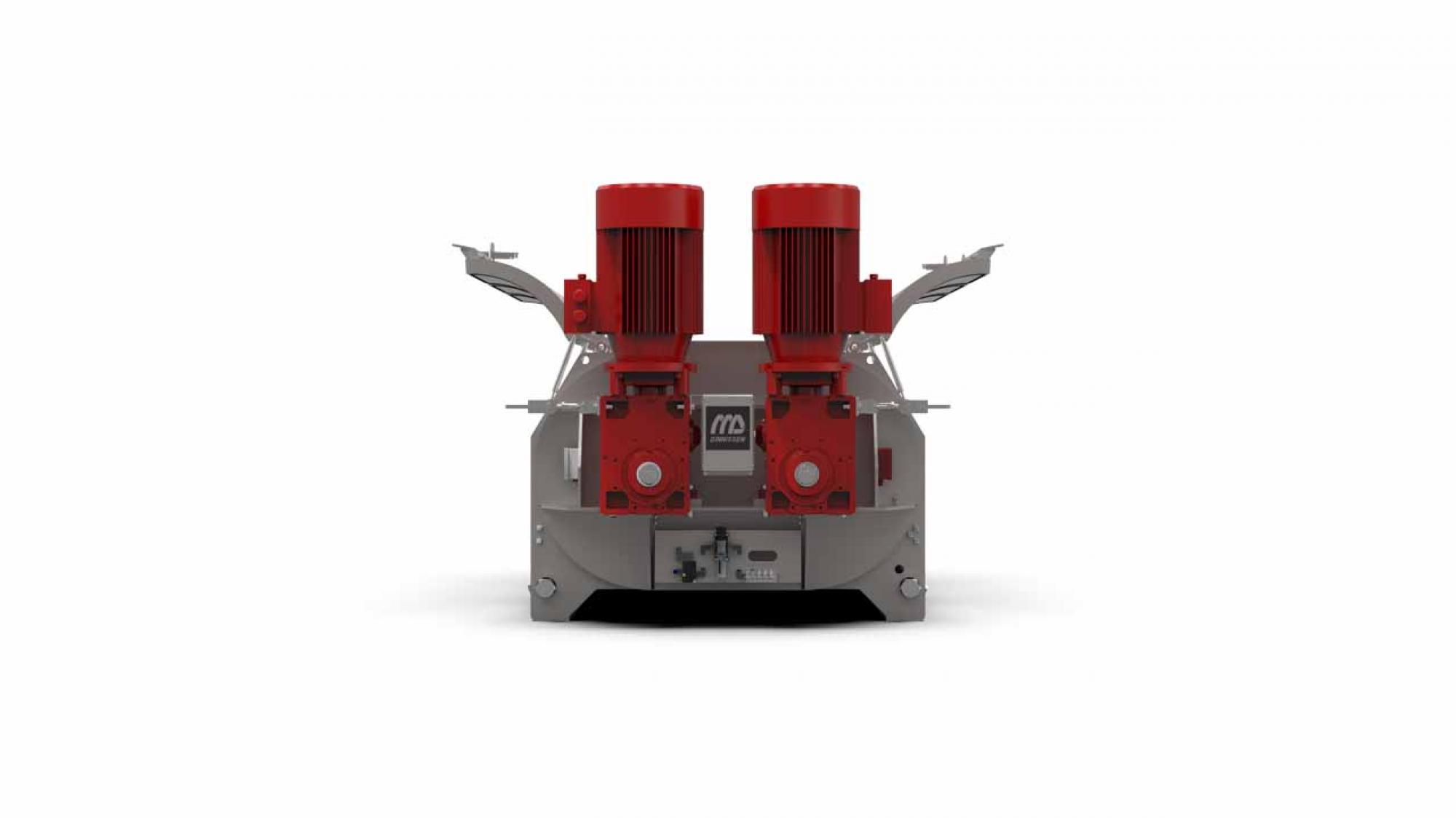

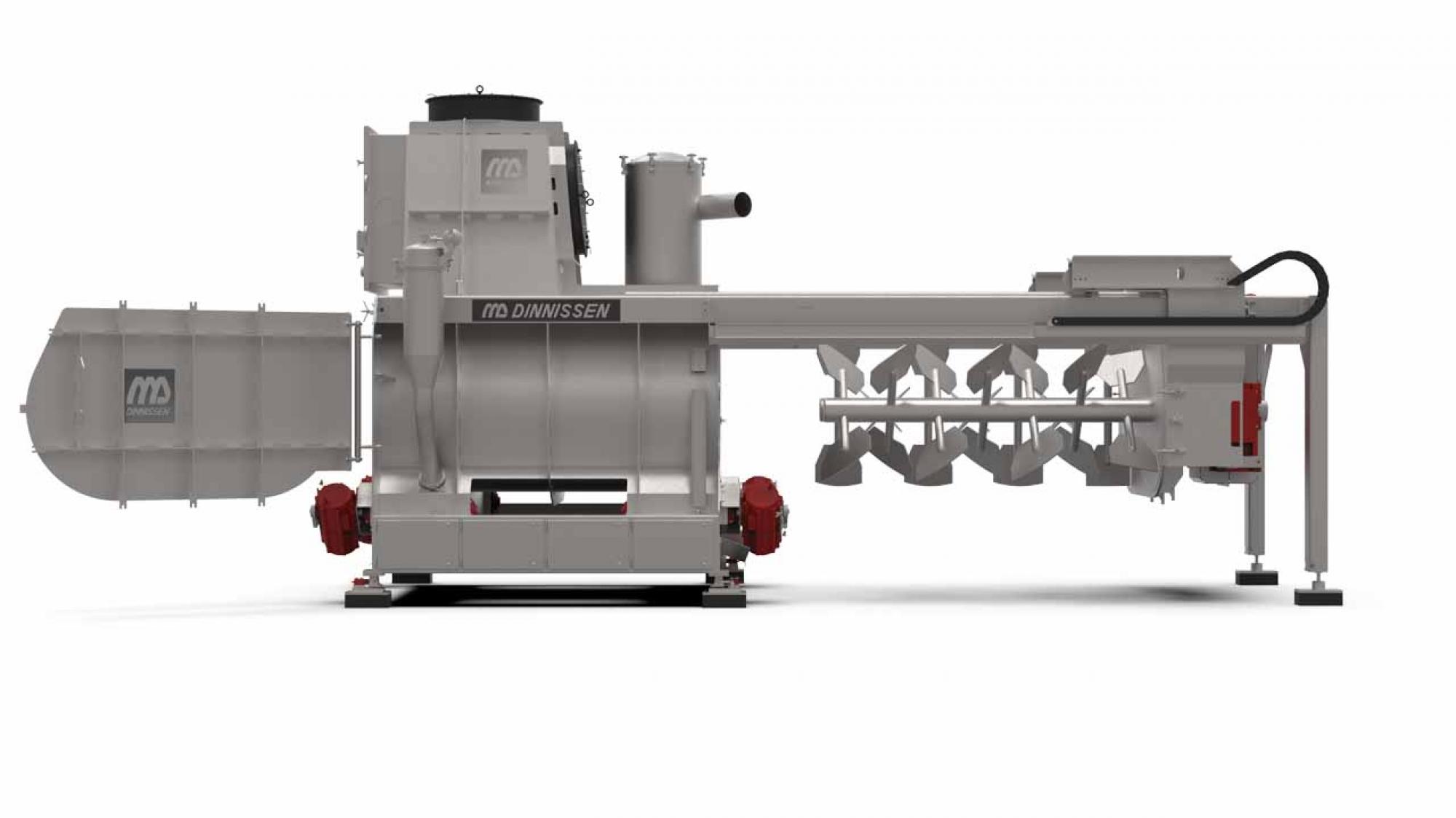

Essentially, all Pegasus® mixers operate on a common principle. At the top, the product is fed into the mixer through an airtight seal. Dual blades, rotating in opposing directions, ensure thorough mixing. Towards the base, hatches open when the desired blend is achieved. In combination with mixing, different processes are possible.

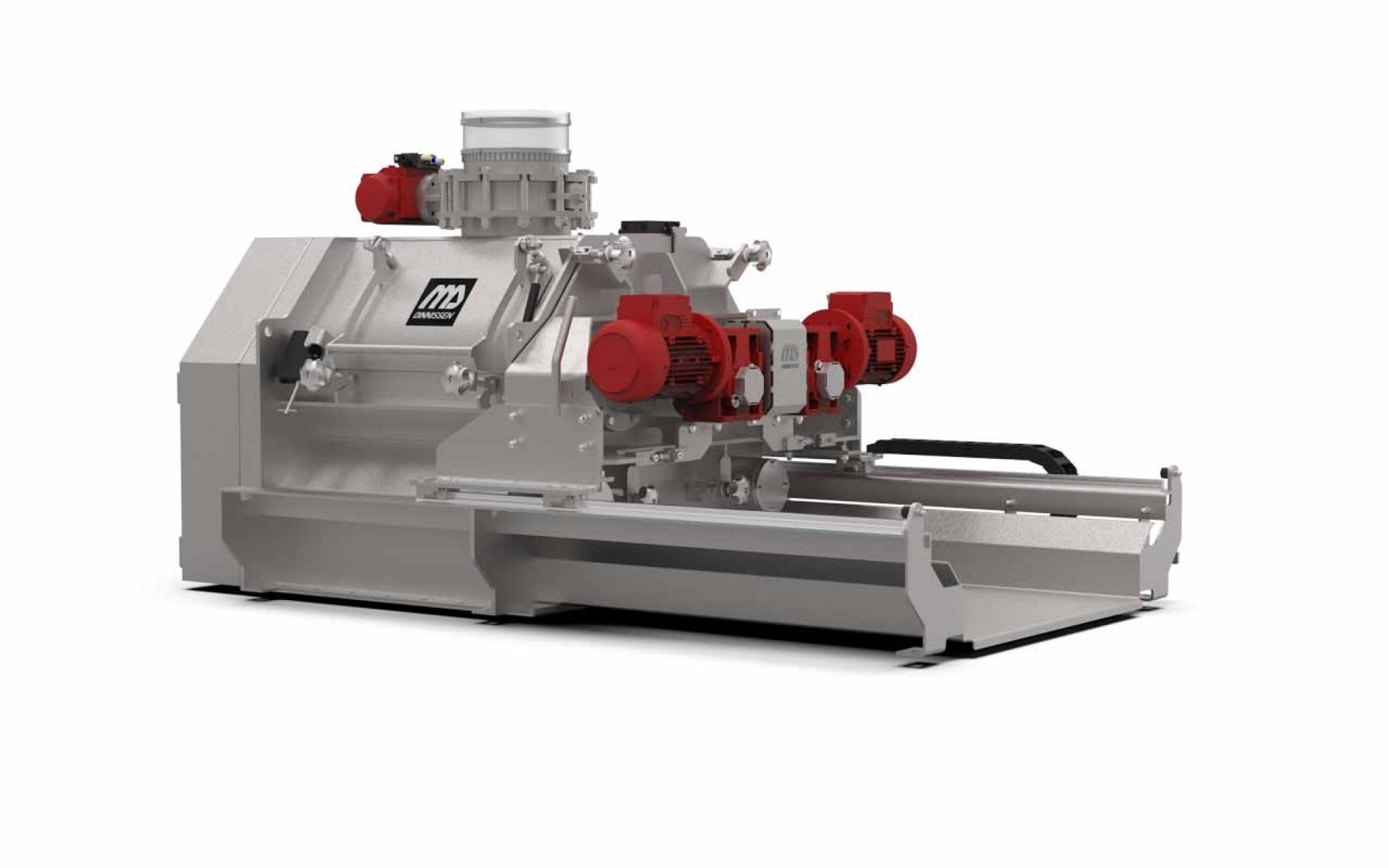

PEGASUS® CONDITIONER

The Pegasus® Conditioner combines diverse bulk materials such as powders, water, steam, and fats, all while preventing de-mixing. This mixer’s unique characteristic is its concurrent heating process, which guarantees uniformity in the mixture. Furthermore, by accurately controlling the temperature, you can precisely determine the moisture content of your product.

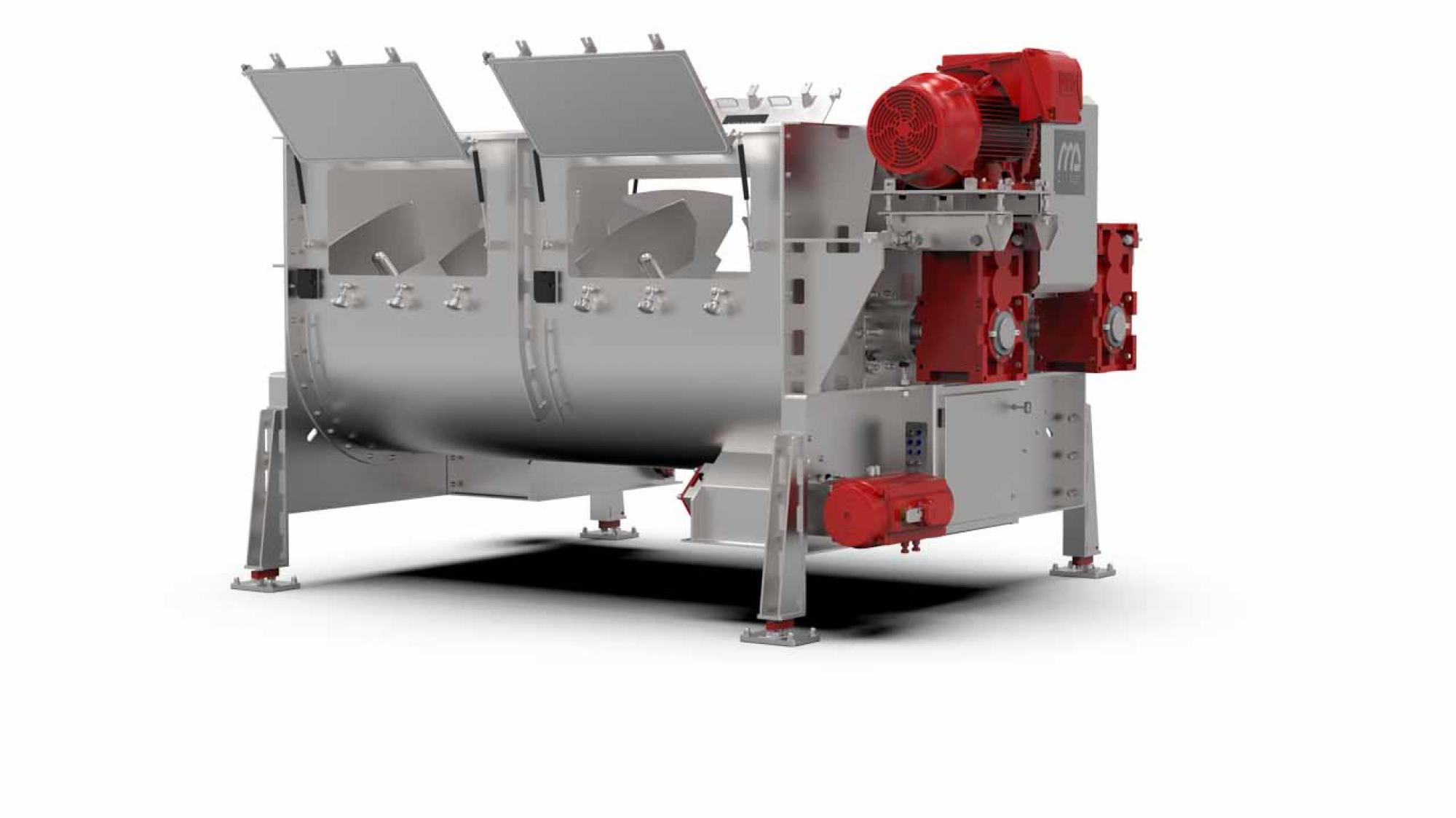

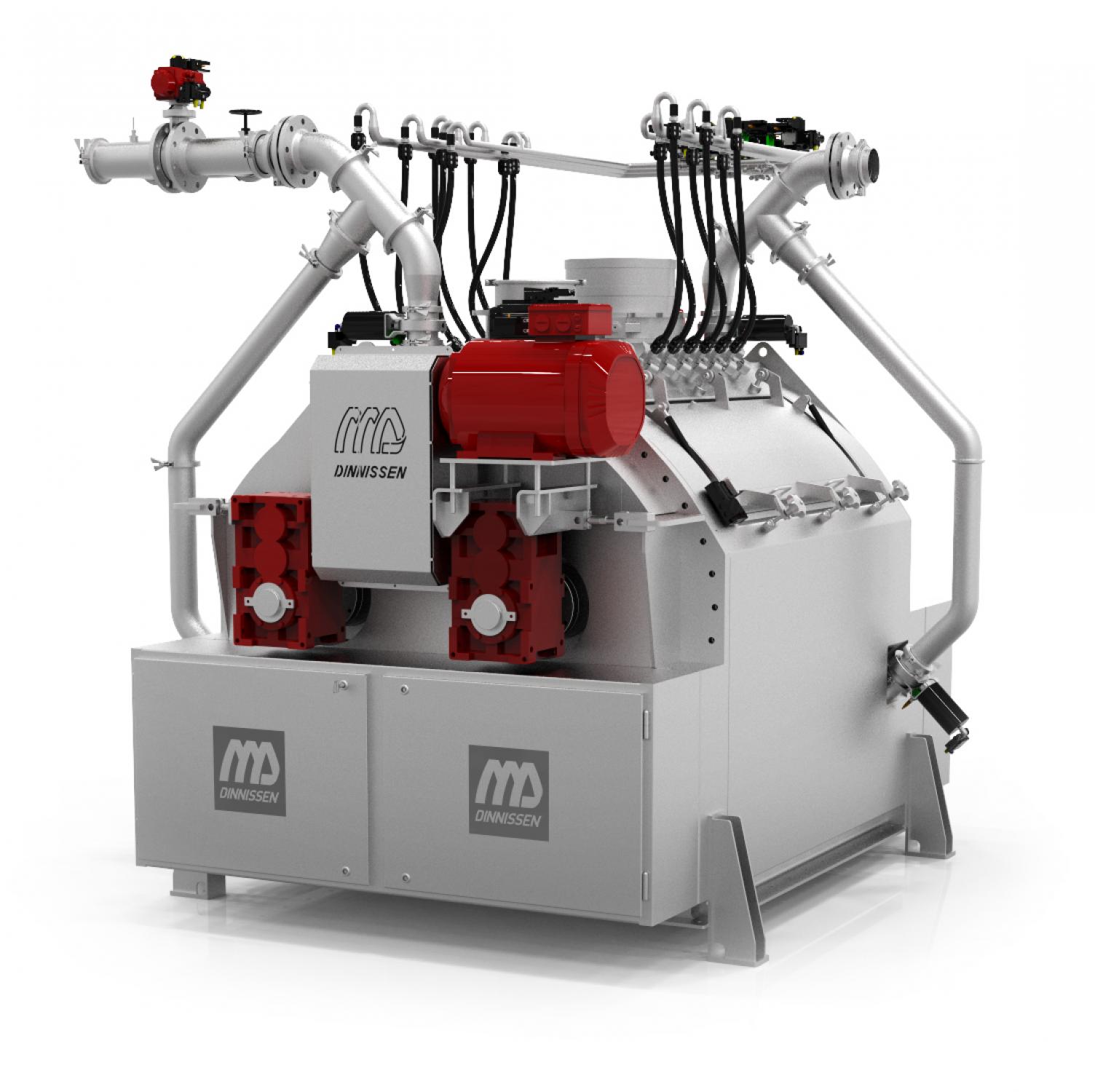

PEGASUS® THERMAL MIXER

Also known as the Thermidor Mixer, The Pegasus® Thermal Mixer utilizes steam to sterilize the product to be mixed. This highly effective system can for example be used as pretreatment or salmonella control. With an astounding 99.999% reduction in microbe populations, this mixer subsequently cools the product to the desired temperature, without any risk of de-mixing.